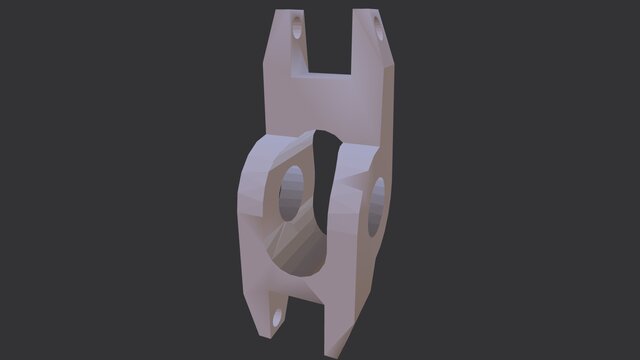

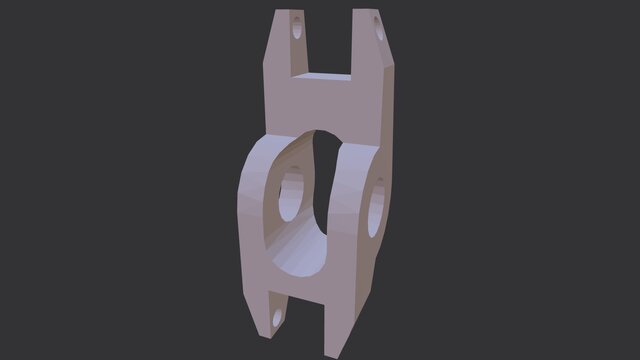

Rocker Arm

Rocker Arm – Precision, Dynamics, and Design Excellence

The rocker arm is a critical mechanical linkage in internal combustion engines, translating the rotational motion of the camshaft into precise linear motion to actuate the intake and exhaust valves. Its design embodies the fusion of structural integrity, lightweight geometry, and dynamic performance.

In CAD modelling, the rocker arm stands out as a component where engineering aesthetics meet functional efficiency:

Functionality: It acts as a lever, transmitting force from the cam lobe to the valve stem with optimised contact geometry for reduced wear and friction.

Design Considerations: Modelled with a balance between stiffness and weight reduction, incorporating fillets, optimised ribbing, and material-specific cross-sections to resist bending and fatigue.

Engineering Significance: Highlights advanced manufacturing strategies such as forging, precision casting, or CNC machining, depending on application requirements.

CAD Value: Demonstrates proficiency in parametric modelling, assembly motion simulation, and stress analysis (FEA), showcasing the ability to engineer components for real-world performance.

The rocker arm is not just a part - it’s an excellent example of how CAD transforms a complex functional requirement into an optimised, manufacturable design that embodies efficiency, reliability, and innovation.

Files (4)

License:

CC - Attribution

Learn more

Published