Project: BIC Pen Reverse Engineering and 3D CAD Modeling

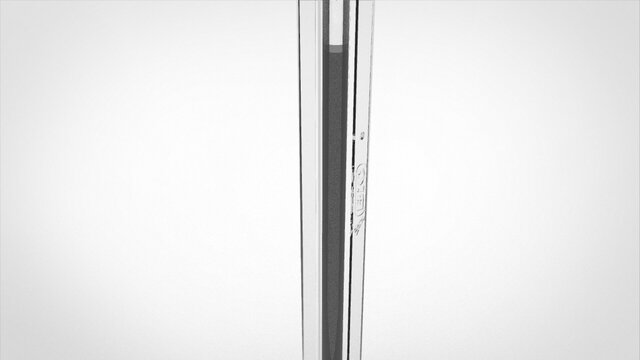

This project involved the detailed reverse engineering and 3D modeling of a classic BIC ballpoint pen using SolidWorks. The goal was to replicate the form, fit, and function of the original design for educational and prototyping purposes.

✅ Key project features:

Accurate modeling of all components (barrel, ink tube, tip, cap)

Use of SolidWorks features such as lofts, revolves, and shelling

Assembly modeling and exploded views

Technical drawings with dimensional tolerances

The project demonstrates expertise in small plastic part design, reverse engineering, and proper CAD structuring. All parts were modeled parametrically to allow design variation for similar stationery products.

The model is optimized for 3D printing, rendering, and presentation, and can be adapted for mold design or production planning.

Files (7)

License:

CC - Attribution

Learn more

Published