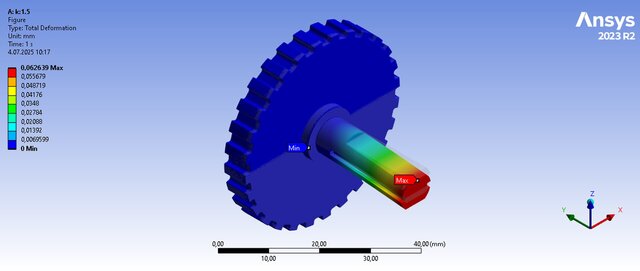

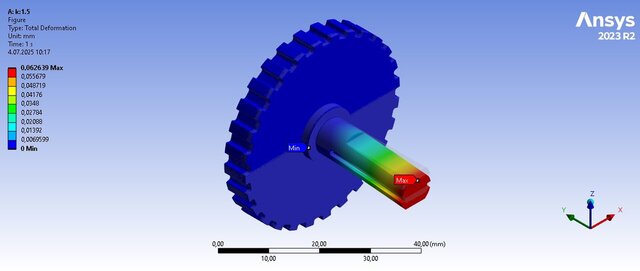

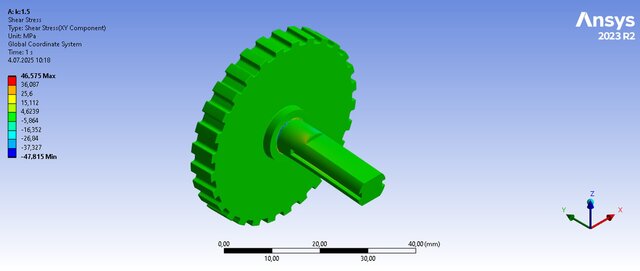

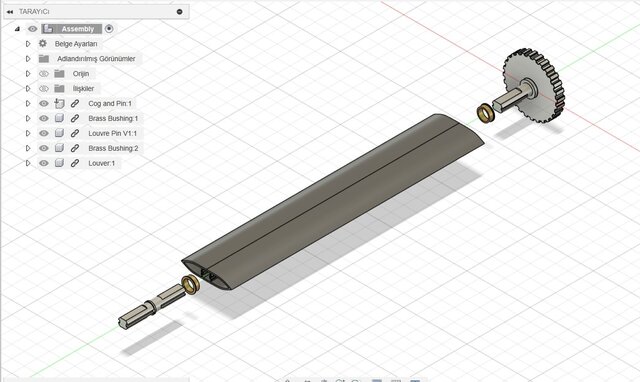

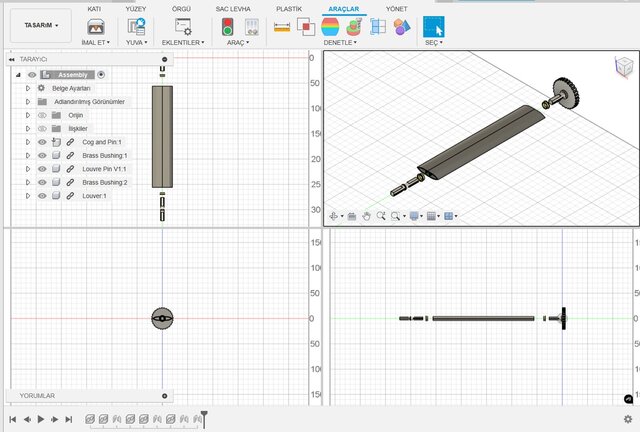

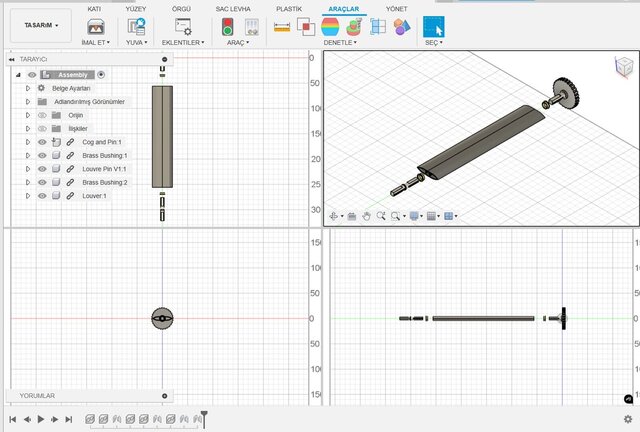

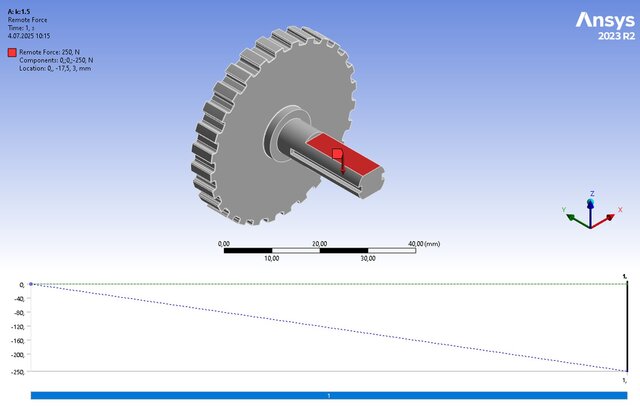

FEA Model Aluminum Part under Load

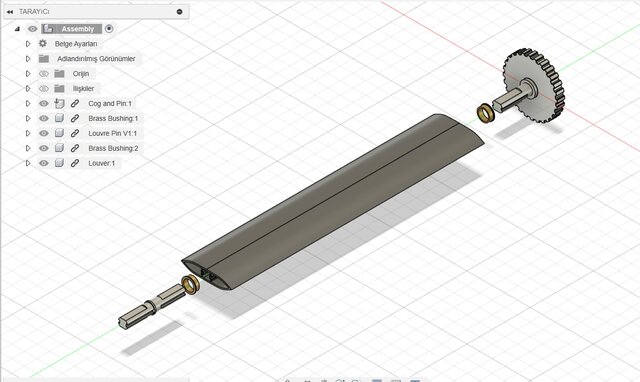

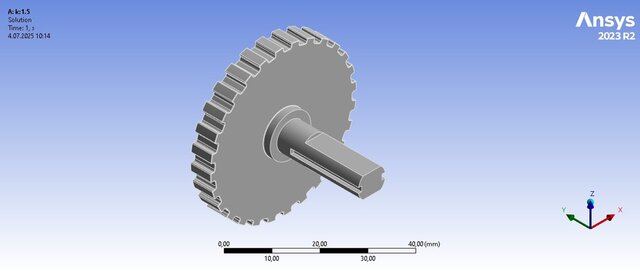

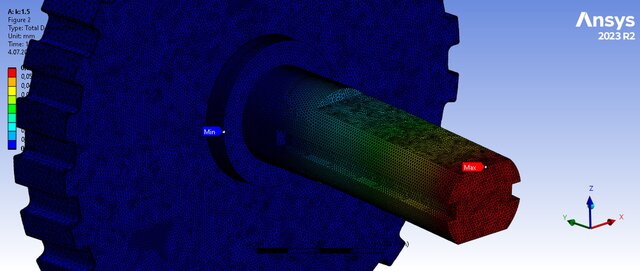

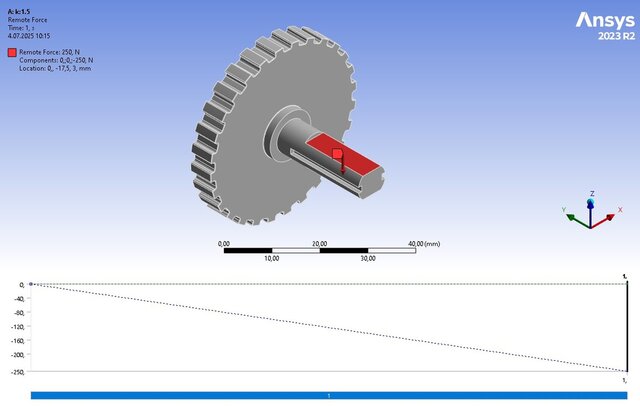

I performed a detailed Finite Element Analysis (FEA) on a custom aluminum part (pin and cog) subjected to a remote force. The assembly was prepared in Fusion 360 and imported into ANSYS Workbench for analysis. The model was meshed, boundary conditions were applied, and deformation and shear stress distributions were obtained. The study demonstrated the maximum deformation of 0.062 mm and shear stress distribution up to 46 MPa under a 250 N force, confirming the design integrity of the part within safe limits. The work also included creating a full CAD assembly with brass bushings and louver housing.

Published