I will create 3D product design from concept to life

About this service

As a plastic product design engineer, I specialize in transforming innovative concepts into practical manufacturing solutions, ensuring that each product not only meets aesthetic and functional requirements but also adheres to industry standards and sustainability practices. My approach is holistic, guiding clients through every stage of the design process, from initial brainstorming to final production.

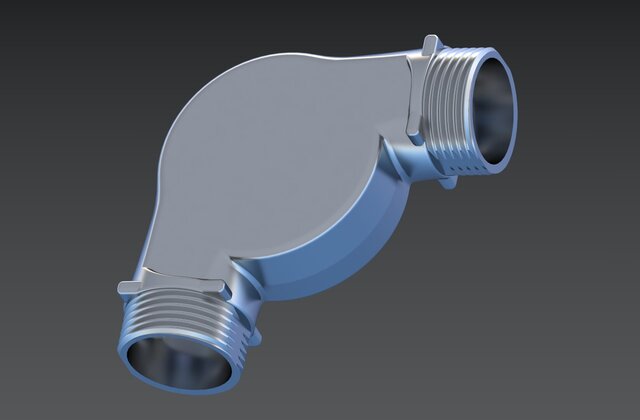

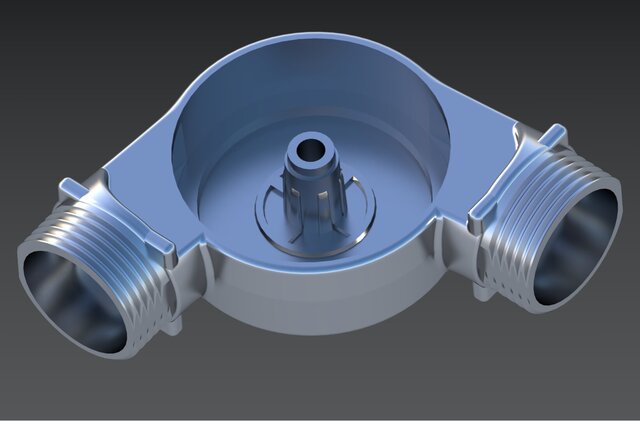

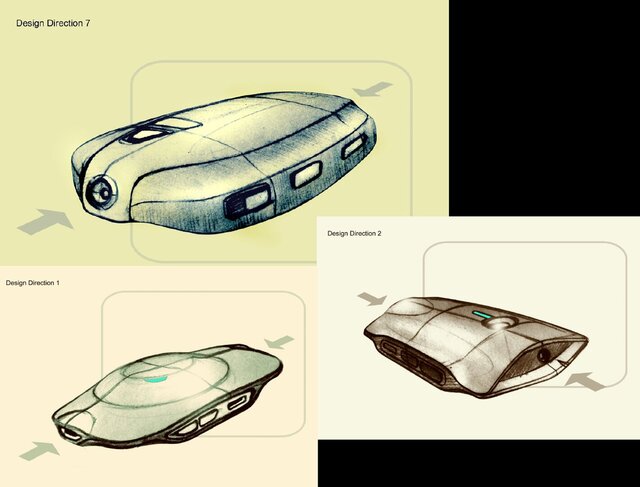

In the conceptual phase, I collaborate closely with clients to understand their vision, market needs, and user requirements. Utilizing advanced design software, I create detailed 3D models and prototypes, allowing for visual representation and functional testing of ideas. This iterative process ensures that we refine the design based on feedback and performance evaluations.

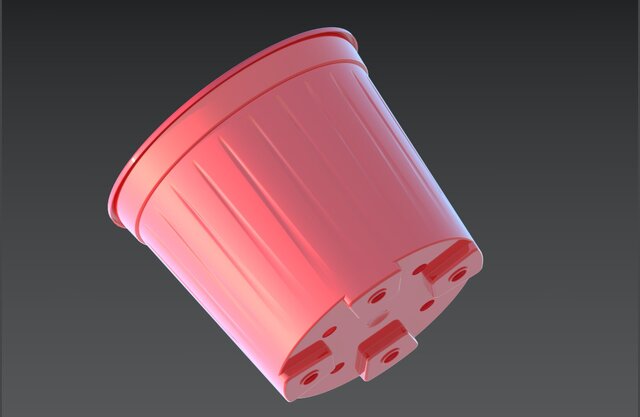

Once the concept is solidified, I focus on material selection, emphasizing the importance of choosing the right type of plastic that balances durability, cost-effectiveness, and environmental impact. I leverage my knowledge of various plastics, including thermoplastics and thermosetting polymers, to recommend the best options for each specific application.

Transitioning from design to manufacturing, I develop comprehensive production plans that include tooling design, process optimization, and quality assurance protocols. I work closely with manufacturers to ensure that the production process aligns with the design specifications, addressing any challenges that may arise during fabrication.

Throughout... read more

In the conceptual phase, I collaborate closely with clients to understand their vision, market needs, and user requirements. Utilizing advanced design software, I create detailed 3D models and prototypes, allowing for visual representation and functional testing of ideas. This iterative process ensures that we refine the design based on feedback and performance evaluations.

Once the concept is solidified, I focus on material selection, emphasizing the importance of choosing the right type of plastic that balances durability, cost-effectiveness, and environmental impact. I leverage my knowledge of various plastics, including thermoplastics and thermosetting polymers, to recommend the best options for each specific application.

Transitioning from design to manufacturing, I develop comprehensive production plans that include tooling design, process optimization, and quality assurance protocols. I work closely with manufacturers to ensure that the production process aligns with the design specifications, addressing any challenges that may arise during fabrication.

Throughout... read more

As a plastic product design engineer, I specialize in transforming innovative concepts into practical manufacturing solutions, ensuring that each product not only meets aesthetic and functional requirements but also adheres to industry standards and sustainability practices. My approach is holistic, guiding clients through every stage of the design process, from initial brainstorming to final production.

In the conceptual phase, I collaborate closely with clients to understand their vision, market needs, and user requirements. Utilizing advanced design software, I create detailed 3D models and prototypes, allowing for visual representation and functional testing of ideas. This iterative process ensures that we refine the design based on feedback and performance evaluations.

Once the concept is solidified, I focus on material selection, emphasizing the importance of choosing the right type of plastic that balances durability, cost-effectiveness, and environmental impact. I leverage my knowledge of various plastics, including thermoplastics and thermosetting polymers, to recommend the best options for each specific application.

Transitioning from design to manufacturing, I develop comprehensive production plans that include tooling design, process optimization, and quality assurance protocols. I work closely with manufacturers to ensure that the production process aligns with the design specifications, addressing any challenges that may arise during fabrication.

Throughout the project, I prioritize communication and collaboration, providing regular updates and incorporating client feedback to ensure satisfaction. My goal is to deliver a final product that not only meets the original vision but also excels in functionality and manufacturability.

In summary, my role as a Plastic Product Design Engineer encompasses the entire journey from concept to practical manufacturing, ensuring that each product is designed with precision, efficiency, and sustainability in mind. Whether it's a consumer product, industrial component, or custom solution, I am dedicated to bringing innovative ideas to life through expert design and engineering practices. read less

In the conceptual phase, I collaborate closely with clients to understand their vision, market needs, and user requirements. Utilizing advanced design software, I create detailed 3D models and prototypes, allowing for visual representation and functional testing of ideas. This iterative process ensures that we refine the design based on feedback and performance evaluations.

Once the concept is solidified, I focus on material selection, emphasizing the importance of choosing the right type of plastic that balances durability, cost-effectiveness, and environmental impact. I leverage my knowledge of various plastics, including thermoplastics and thermosetting polymers, to recommend the best options for each specific application.

Transitioning from design to manufacturing, I develop comprehensive production plans that include tooling design, process optimization, and quality assurance protocols. I work closely with manufacturers to ensure that the production process aligns with the design specifications, addressing any challenges that may arise during fabrication.

Throughout the project, I prioritize communication and collaboration, providing regular updates and incorporating client feedback to ensure satisfaction. My goal is to deliver a final product that not only meets the original vision but also excels in functionality and manufacturability.

In summary, my role as a Plastic Product Design Engineer encompasses the entire journey from concept to practical manufacturing, ensuring that each product is designed with precision, efficiency, and sustainability in mind. Whether it's a consumer product, industrial component, or custom solution, I am dedicated to bringing innovative ideas to life through expert design and engineering practices. read less

As a plastic product design engineer, I specialize in transforming innovative concepts into practical manufacturing solutions, ensuring that each product not only meets aesthetic and functional requirements but also adheres to industry standards and sustainability practices. My approach is holistic, guiding clients through every stage of the design process, from initial brainstorming to final prod...

read more

As a plastic product design engineer, I specialize in transforming innovative concepts into practical manufacturing solutions, ensuring that each product not only meets aesthetic and functional requirements but also adheres to industry standards and sustainability practices. My approach is holistic, guiding clients through every stage of the design process, from initial brainstorming to final production.

In the conceptual phase, I collaborate closely with clients to understand their vision, market needs, and user requirements. Utilizing advanced design software, I create detailed 3D models and prototypes, allowing for visual representation and functional testing of ideas. This iterative process ensures that we refine the design based on feedback and performance evaluations.

Once the concept is solidified, I focus on material selection, emphasizing the importance of choosing the right type of plastic that balances durability, cost-effectiveness, and environmental impact. I leverage my knowledge of various plastics, including thermoplastics and thermosetting polymers, to recommend the best options for each specific application.

Transitioning from design to manufacturing, I develop comprehensive production plans that include tooling design, process optimization, and quality assurance protocols. I work closely with manufacturers to ensure that the production process aligns with the design specifications, addressing any challenges that may arise during fabrication.

Throughout the project, I prioritize communication and collaboration, providing regular updates and incorporating client feedback to ensure satisfaction. My goal is to deliver a final product that not only meets the original vision but also excels in functionality and manufacturability.

In summary, my role as a Plastic Product Design Engineer encompasses the entire journey from concept to practical manufacturing, ensuring that each product is designed with precision, efficiency, and sustainability in mind. Whether it's a consumer product, industrial component, or custom solution, I am dedicated to bringing innovative ideas to life through expert design and engineering practices. read less

In the conceptual phase, I collaborate closely with clients to understand their vision, market needs, and user requirements. Utilizing advanced design software, I create detailed 3D models and prototypes, allowing for visual representation and functional testing of ideas. This iterative process ensures that we refine the design based on feedback and performance evaluations.

Once the concept is solidified, I focus on material selection, emphasizing the importance of choosing the right type of plastic that balances durability, cost-effectiveness, and environmental impact. I leverage my knowledge of various plastics, including thermoplastics and thermosetting polymers, to recommend the best options for each specific application.

Transitioning from design to manufacturing, I develop comprehensive production plans that include tooling design, process optimization, and quality assurance protocols. I work closely with manufacturers to ensure that the production process aligns with the design specifications, addressing any challenges that may arise during fabrication.

Throughout the project, I prioritize communication and collaboration, providing regular updates and incorporating client feedback to ensure satisfaction. My goal is to deliver a final product that not only meets the original vision but also excels in functionality and manufacturability.

In summary, my role as a Plastic Product Design Engineer encompasses the entire journey from concept to practical manufacturing, ensuring that each product is designed with precision, efficiency, and sustainability in mind. Whether it's a consumer product, industrial component, or custom solution, I am dedicated to bringing innovative ideas to life through expert design and engineering practices. read less

Service offer categories

Design for Manufacturability (DFM Services)

Engineering Design

Industrial Design Services

Software & skills

3D CAD Design

3D Modeling

3D Prototyping

Advanced 3D Modeling

Advanced Manufacturing

CAD Design and Drafting

CAD Modeling

CAD Simulation

Plastic Product Design

Tooling Design

+7 more

Member since

May 2022

Languages

English,

Hindi,

Gujarati

Avg. response time

1 hour

Mechanical Engineer working as a Product Development Engineer-Software's (UGI NX & SOLIDWORKS)

-Industrial product design engineer

-Injection mold designer (More than 5 years of experience)

-3D design highly suited for 3D printing

-conversion from .stl or .obj to .step To any needed extension file

- Enclosure Concept design

- Product rendering using keyshot

- Bottle, packaging, household items, and more

- conversion from hand sketch to CAD 3D

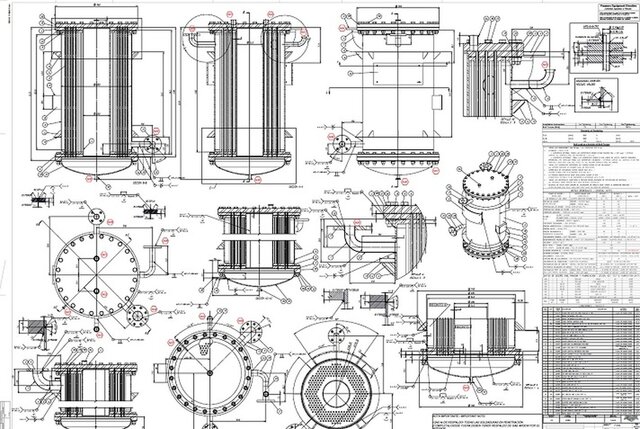

- Technical 2D drawing for manufacturing

~~~MO... read more

-Injection mold designer (More than 5 years of experience)

-3D design highly suited for 3D printing

-conversion from .stl or .obj to .step To any needed extension file

- Enclosure Concept design

- Product rendering using keyshot

- Bottle, packaging, household items, and more

- conversion from hand sketch to CAD 3D

- Technical 2D drawing for manufacturing

~~~MO... read more

Cad Crowd Billing Security policy

Service quality is protected by Cad Crowd Billing Security policy.

More from Abizz Services #.

More similar services

See related services

- 3D Design services

- 3D Modeling services

- CAD Design services

- 2D & 3D Design services

- 2D & 3D Modeling services

- CAD Modeling services

- Drafting services

- Engineering Design services

- Product Design services

- AutoCAD services

- Rendering services

- CAD Drafting services

- Mechanical Design services

- 2D Drafting services

- 3D Rendering services

- 3D Models services

- 2D Drawing services

- Mechanical 3D Design services

- 2D AutoCAD services

- Design for Manufacturing services

- SolidWorks services

- 3D Solidworks services

- 2D & 3D Drafting services

- Mechanical Engineering services

- 2D/3D AutoCAD services

- 2D & 3D Modeling Solidworks services

- Concept Design services

- Assembly Design services

- 3D Printing Design services

- Engineering Drawing services

- CAD Assembly services

- FEA services

- Industrial Design services

- Design Engineer services

- Mechanical Engineer services

- 2D and 3D Mechanical Drafting services