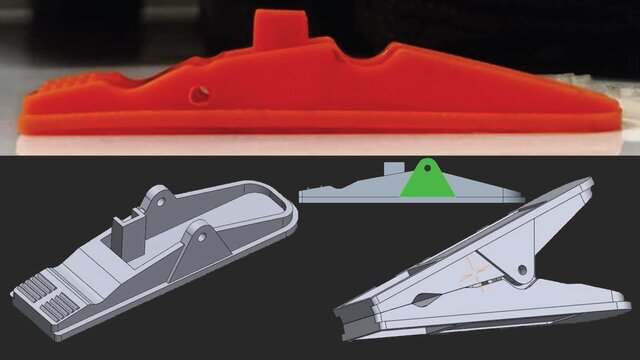

I offer manufacturing failure diagnosis (injection + die casting)

About this service

Send photos, drawings, or sample descriptions.

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

Send photos, drawings, or sample descriptions.

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

Send photos, drawings, or sample descriptions.

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

Send photos, drawings, or sample descriptions.

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

I identify root cause based on production behavior - material, tooling or process.

Examples of issues solved

• Injection warpage

• Die casting porosity

• Short shots

• Mold sticking

• Dimensional instability

Deliverables

• Root cause explanation

• Corrective actions

• Tool or process modification advice

Service offer categories

Tool Design Services

Mold and Die Design Services

Injection Molding Design

Software & skills

Die Casting

Injection Molding

Manufacturing Processes

Problem Resolution

Process Improvement

Root Cause Analysis

Tooling Design

+4 more

This service includes

| Service tiers | Simple $100 | Standard $200 | Advanced $500 |

|---|---|---|---|

| Summary | Root Cause Snapshot | Engineering Diagnosis Report | Corrective Action & Prevention Plan |

| Details | Quick diagnosis of the most likely root cause using your photos, dimensions, and process notes, with immediate corrective suggestions. | Structured defect analysis (design vs tooling vs process), likely mechanism explanation, and prioritized corrective actions you can apply in production. | Full troubleshooting plan with recommended design/tool/process modifications, prevention checklist, and guidance to stabilize quality over multiple production runs. |

| Delivery time | 2 days | 4 days | 7 days |

| Number of revisions | 1 | 2 | 4 |

Member since

February 2026

Languages

Arabic,

English

Avg. response time

1 hour

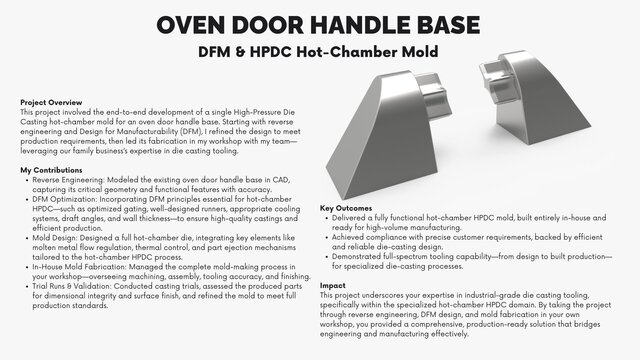

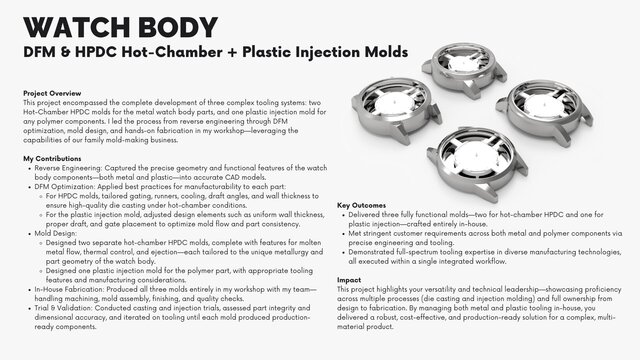

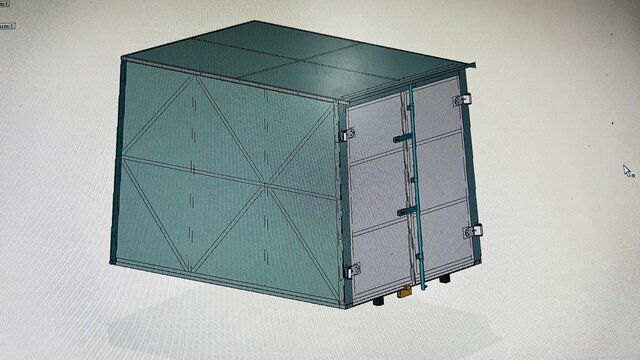

Senior Mechanical Designer | DFM & Tooling Consultant

I am a senior mechanical and industrial design engineer with over 20 years of hands-on experience in product design, tooling, and manufacturing systems.

My work focuses on design for manufacturing, where ideas are shaped with real production constraints in mind—materials, tolerances, tooling limits, cost, and reliability. I have designed and reviewed hundreds of molds, dies, and production compon... read more

My work focuses on design for manufacturing, where ideas are shaped with real production constraints in mind—materials, tolerances, tooling limits, cost, and reliability. I have designed and reviewed hundreds of molds, dies, and production compon... read more

Cad Crowd Billing Security policy

Service quality is protected by Cad Crowd Billing Security policy.

More from Mohamed R.

More similar services

See related services

- 3D Design services

- 3D Modeling services

- CAD Design services

- 2D & 3D Design services

- 2D & 3D Modeling services

- Drafting services

- Engineering Design services

- Product Design services

- AutoCAD services

- Rendering services

- 3D Models services

- Mechanical Design services

- 3D Rendering services

- 2D Drawing services

- Mechanical 3D Design services

- Design for Manufacturing services

- 2D AutoCAD services

- SolidWorks services

- 3D Solidworks services

- Mechanical Engineering services

- 2D/3D AutoCAD services

- 2D & 3D Modeling Solidworks services

- Concept Design services

- Assembly Design services

- Industrial Design services

- CAD Assembly services

- Design Engineer services

- FEA services

- Part Design services

- Mechanical Engineer services

- Prototyping services

- 2D and 3D Mechanical Drafting services

- AutoCAD Mechanical services

- 3D Assembly Drawings services

- Product Development services

- Product Design and Development services