WindTurbine Spur Gear Design

# WindTurbine Spur Gear Design (Gear-Box)

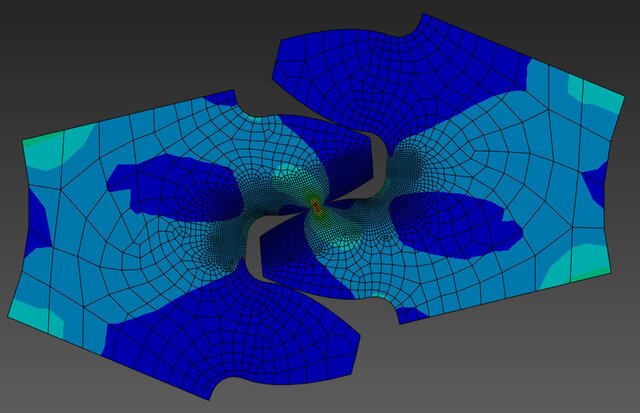

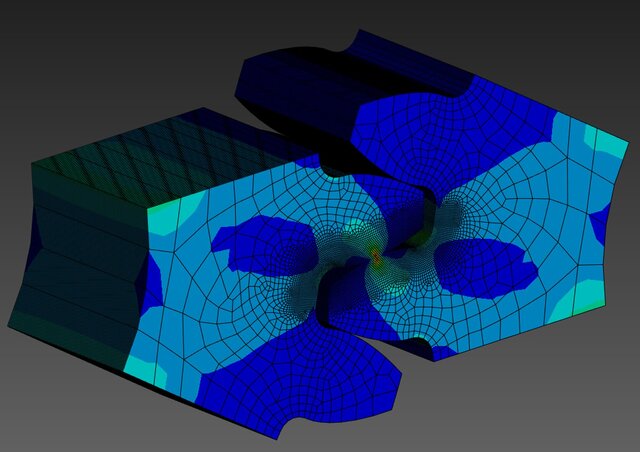

A failure investigation was conducted on a spur gear design due to observed tooth degradation in a wind turbine gearbox. FEA was utilized to assess the **Hertzian** contact stresses between the gear teeth, providing critical insight into the stress distribution and potential failure mechanisms.

The analysis included a detailed evaluation of mesh sensitivity to ensure accurate capture of stress concentrations, which are essential for understanding localized fatigue and wear.

Additionally, a fatigue life assessment was performed to evaluate the gear’s durability under cyclic loading conditions. By refining the mesh in high-stress regions and incorporating fatigue analysis, the study aimed to improve the accuracy of stress predictions and estimate the gear’s operational lifespan, ultimately contributing to enhanced reliability and performance of the gearbox system.

Published