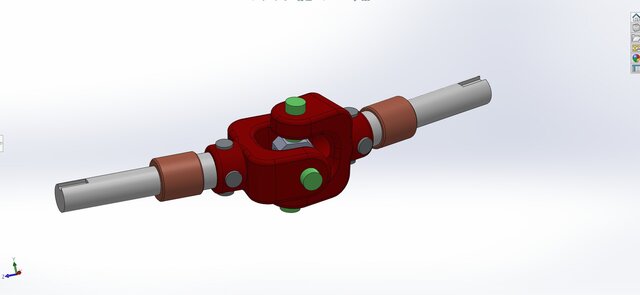

universal-coupling

A universal coupling can be modeled by creating the two yokes, the central cross (spider), and the connecting pins as separate parts and then assembling them together. The yokes are designed with arms that hold the pins, while the cross links them at right angles. Once assembled with proper mates, the coupling can demonstrate its unique motion — allowing shafts to transmit power even when they are not in perfect alignment. It’s a very useful part to model as it clearly shows how mechanical systems handle angular misalignment in real applications.

Files (2)

License:

CC - Attribution

Learn more

Published

in

CAD Design