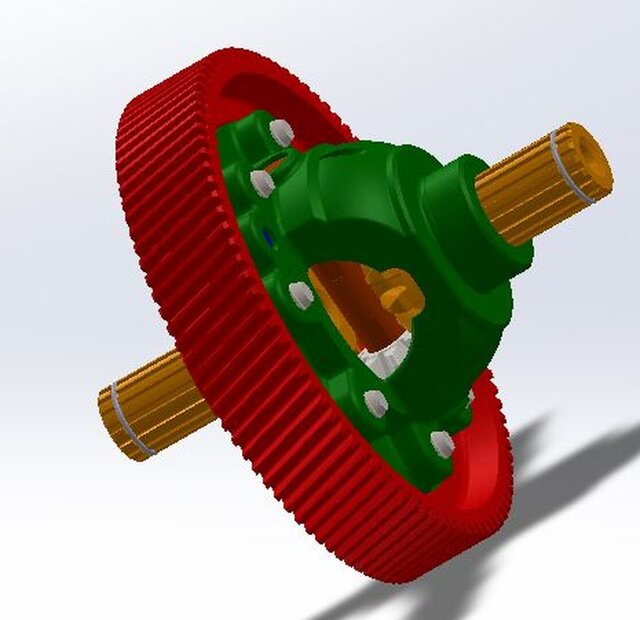

Three Wheeler Differential

Our project focused on the reverse engineering of a three-wheeler differential, followed by the development of its child parts directly on the shop floor. The objective was to understand the internal design and functionality of the differential and replicate its components using in-house manufacturing processes.

The process began with the careful disassembly of the original differential unit. Each component—gears, shafts, bearings, and casing—was inspected and measured using precision instruments such as Vernier calipers, micrometers, and coordinate measuring machines (CMM). Material properties were identified through hardness testing and visual inspection, helping us select appropriate raw materials for replication.

Once the reverse engineering phase was complete, we transitioned to the development of child parts on the shop floor. This involved planning machining operations for each component. Gear cutting was performed using hobbing. machines, while shafts and housings were produced through turning and milling. Heat treatment was applied to critical components to enhance durability and wear resistance.

Quality control played a vital role throughout the process. Each part was inspected for dimensional accuracy, surface finish, and tolerance compliance. Fitment trials ensured proper assembly and smooth operation of the differential. The final assembly was tested for torque transmission, rotational balance, and noise levels.

This hands-on project provided valuable insights into mechanical design, manufacturing techniques, and quality assurance. It demonstrated our ability to replicate complex automotive components and highlighted opportunities for design optimization and cost-effective production