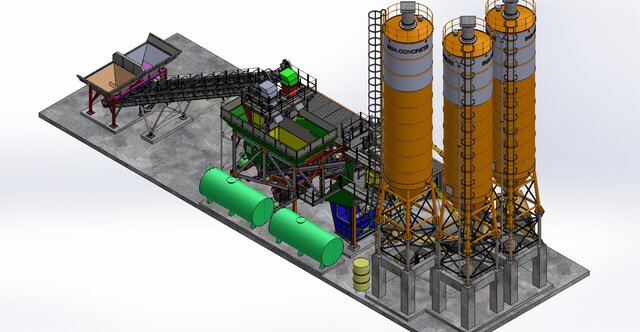

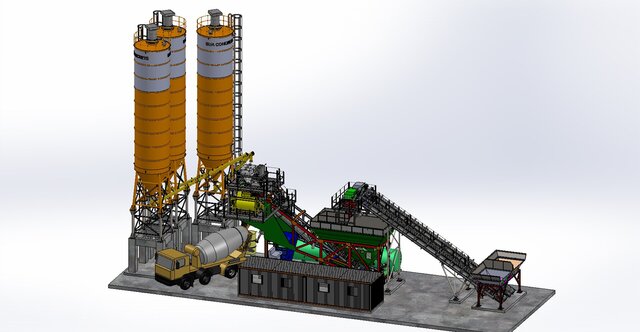

Steel Structure Design for a Concrete Batching Plant in Germany

Introduction

Yas Tech services specialize in designing robust steel structures for industrial applications, delivering solutions that meet stringent safety and regulatory standards. Our recent project involved designing a steel structure for a concrete batching plant in Germany, a critical facility for producing high-quality concrete. This case study highlights our expertise in overcoming technical challenges, ensuring compliance with European standards, and enhancing operational efficiency, offering insights relevant to engineering firms in the construction sector.

Project Scope

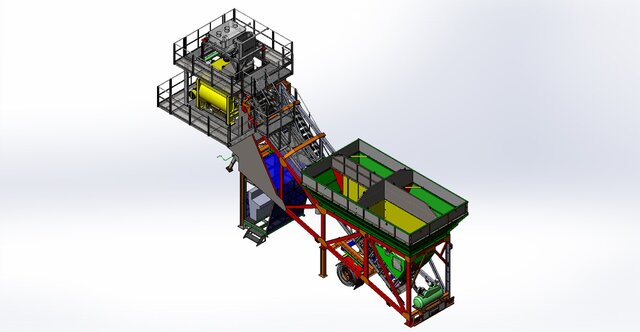

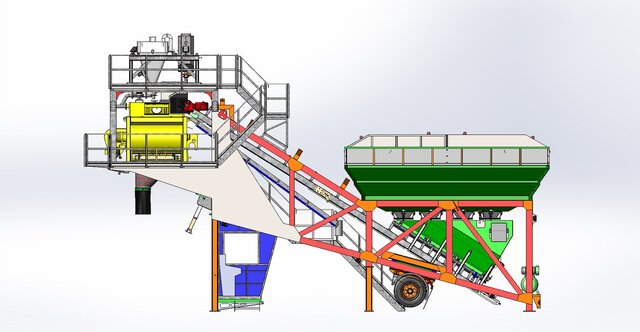

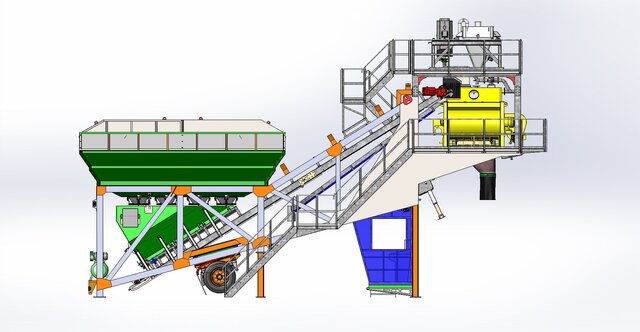

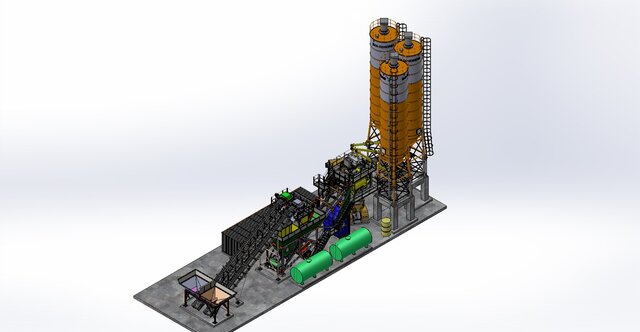

The project entailed designing a steel structure for a static concrete batching plant with a capacity of 60 m³ per hour, located in Germany. The structure supported heavy equipment, including aggregate bins, cement silos, and a twin-shaft mixer, within a compact footprint. The design needed to integrate with existing site infrastructure, withstand environmental and operational loads, and comply with European CE standards and local German building codes.

Technical Challenges

Designing steel structures for concrete batching plants involves complex technical hurdles:

• Heavy and Dynamic Loads: The structure had to support significant dead loads from silos and live loads from the batching process, requiring precise load distribution to prevent failure.

• Corrosion Resistance: Exposure to moisture, cement dust, and chemicals demanded materials that could withstand harsh conditions over time.

• Spatial Constraints: The compact site required an efficient layout to accommodate all components without compromising accessibility or functionality.

• Vibration Control: Dynamic loads from the mixer and conveyors necessitated vibration mitigation to ensure equipment accuracy and structural longevity.

• Safety Integration: Incorporating safety features like guardrails, non-slip surfaces, and dust control systems was critical to protect workers in a high-risk environment.

Regulatory and Industry Norms

The design adhered to rigorous European standards:

• EN 1993 (Eurocode 3): Governed steel structure design, ensuring strength, stability, and durability (Eurocode 3).

• EN 1991 (Eurocode 1): Addressed actions on structures, including wind, snow, and operational loads (Eurocode 1).

• CE Marking: Ensured compliance with health, safety, and environmental protection requirements for construction equipment.

• Local German Building Codes: Mandated additional safety measures, such as fire resistance and emergency access. Industry norms emphasized durability, modular design for future adaptability, and efficient material handling, aligning with best practices for concrete batching plants (Total Batching Solutions).

Software Utilized

Our team leveraged advanced software for precision and efficiency:

• Tekla Structures: Used for 3D modelling, detailing, and clash detection, ensuring accurate fabrication and integration.

• Tekla Structural designer (TSD): Conducted finite element analysis to simulate static and dynamic loads, optimizing structural performance.

• AutoCAD: Supported detailed drafting and documentation for fabrication.

Solutions and Approach

Our approach combined technical expertise with client collaboration:

• Load Management: TSD simulations optimized column and beam placements, ensuring stability under heavy and dynamic loads.

• Corrosion Protection: High-strength, corrosion-resistant steel with protective coatings was selected to enhance durability in the harsh environment.

• Compact Design: Tekla Structures enabled a vertically stacked layout, maximizing space efficiency while maintaining maintenance access.

• Safety Features: Mist rings at discharge points reduced dust, and guardrails with non-slip surfaces met safety standards. Silo safety systems prevented overpressure incidents.

• Vibration Mitigation: Vibration-dampening mounts were incorporated to minimize transmission, ensuring batching accuracy.

• Regulatory Compliance: Rigorous design reviews ensured adherence to Eurocode 3, CE marking, and local codes, facilitating smooth permitting.

Project Outcomes

The concrete batching plant was successfully designed, fabricated, and installed, delivering key benefits:

• Operational Efficiency: The compact, robust structure supported high-volume production, meeting tight project schedules.

• Enhanced Safety: Safety features created a secure working environment, reducing risks for operators.

• Durability: Corrosion-resistant materials ensured a long service life with minimal maintenance.

• Regulatory Compliance: Full adherence to European standards secured regulatory approval and client confidence. The client commended the project’s quality, timely delivery, and compliance, noting improved production efficiency and reduced operational costs.

Conclusion

This project underscores our team’s expertise in designing steel structures for concrete batching plants, addressing technical challenges like load management and corrosion resistance while ensuring compliance with European standards. By leveraging advanced software like Tekla Structures and TSD, we delivered a high-performance, safe, and durable solution. Our commitment to innovation and quality makes us a trusted partner for industrial engineering projects, offering valuable insights for firms seeking reliable structural solutions.