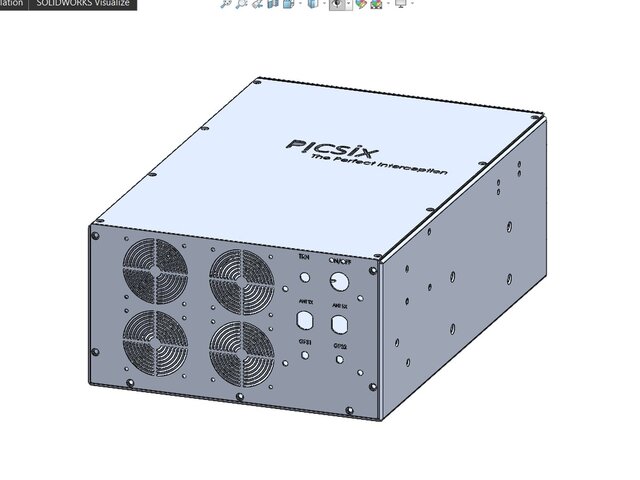

Sheet Metal Enclosure

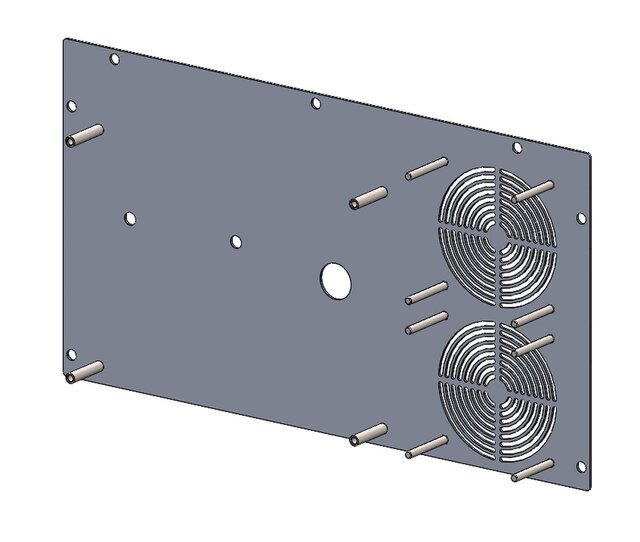

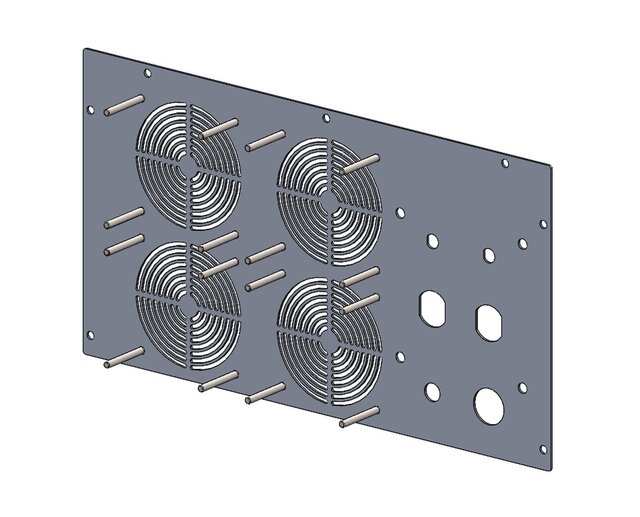

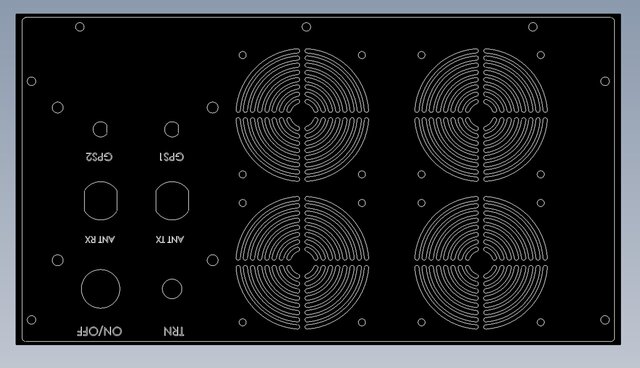

This project showcases a precision-engineered sheet metal enclosure designed for real-world manufacturing and assembly. The enclosure was modeled with accurate bends, flanges, cut-outs, ventilation features, and mounting provisions, ensuring strength, functionality, and ease of fabrication.

The design includes fully defined sheet metal parameters such as bend allowances, K-factors, and corner reliefs, making it suitable for laser cutting, CNC punching, and press-brake forming. Flat patterns and detailed 2D drawings are provided for seamless production.

Key Features:

3D sheet metal CAD modeling

Manufacturable bend and flange design

Vent slots & mounting holes

Assembly-ready structure

Flat pattern & 2D fabrication drawings

Designed using industry-standard CAD tools, this enclosure is ideal for electronics housings, control panels, industrial equipment, and custom fabrication projects.