Pressure Vessel Analysis

# Structural Analysis and Design of a Pneumatic Pressure Vessel

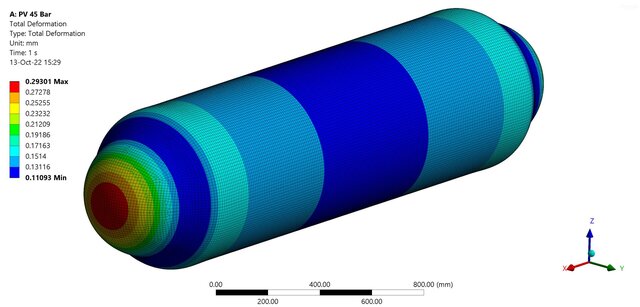

In the design of a pneumatic pressure vessel, I performed a comprehensive structural analysis in accordance with **ASME Section VIII Division 1** guidelines to determine both allowable working pressures and bursting limits. The analysis involved calculating hoop, longitudinal (membrane), and bending stresses under internal pressurization to ensure structural integrity across all operating scenarios.

To verify analytical results and capture localized stress concentrations, a detailed FEA was conducted using high-resolution meshing in critical areas such as weld seams, nozzles, and dome-cylinder junctions. The simulation was extended to include operational load cases as well as extreme pressure conditions, helping to predict failure modes and validate safety margins.

**Hoop stress** is the stress acting tangentially around the circumference of a cylindrical pressure vessel, caused by internal pressure trying to expand the vessel outward. It is typically the largest principal stress and a critical factor in determining wall thickness.

**Axial stress** acts along the length of the cylinder and is generally half the magnitude of hoop stress in thin-walled vessels. Both stresses must be considered to ensure the vessel's structural integrity under pressure.

**ASME code compliance** was central to the design process, governing decisions on material selection, joint efficiency, wall thickness, and factor of safety. By integrating code-based calculations with simulation-driven insights, the design achieved both regulatory conformance and material efficiency, reducing unnecessary weight while ensuring robust performance. This approach provided a solid engineering foundation for a safe, efficient, and certifiable pneumatic pressure vessel.

Published