PMA controller

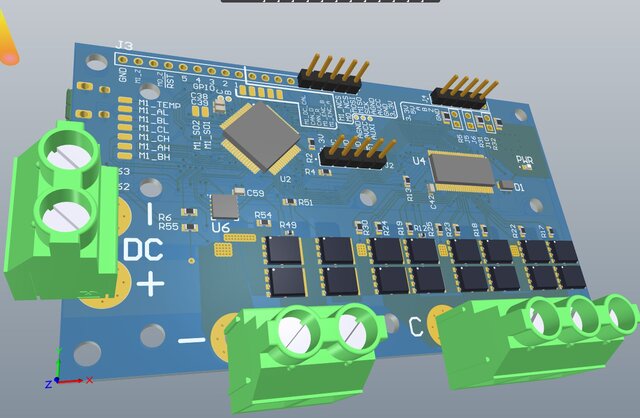

#Designed a robust, low-cost, high-power motor controller PCB tailored for Permanent Magnet Alternator (PMA) systems, capable of handling sustained 50 A current

##Scope & Objectives:

Support a PMA with a sustained 50 A current throughput

Ensure rugged performance in noisy electromechanical environments

Maintain manufacturability and cost-effectiveness

##Challenges:

Managing heat dissipation and power density at high current

Mitigating electromagnetic interference (EMI) generated by alternator operation

Optimizing layout for robustness while keeping PCB size and bill of materials (BOM) minimal

##Key Contributions:

-High-power layout optimization: Balanced trace width, copper weight, and thermal reliefs to safely manage 50 A with minimal thermal build-up

-EMI control techniques: Employed precise placement of decoupling, ground pours, and isolation strategies to reduce radiated and conducted noise

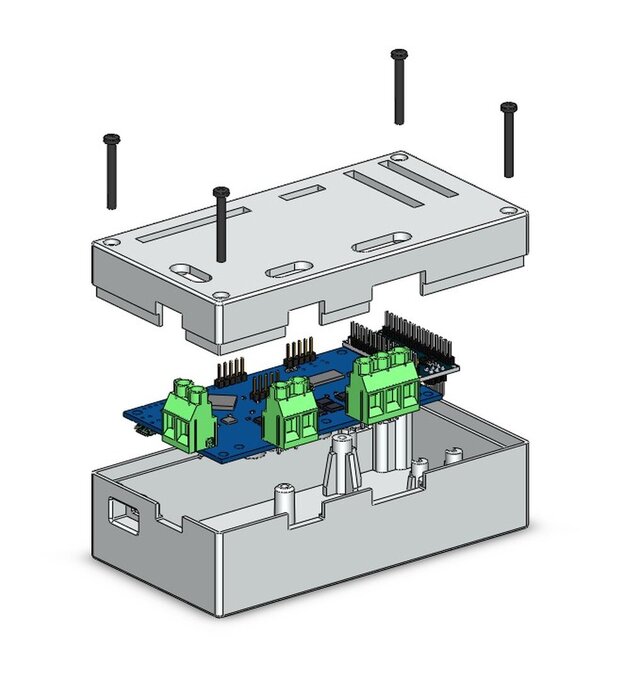

-Modular & user-friendly design: Included clear connectors, test points, and simplified component footprints to streamline assembly and servicing

-3D rendered presentation: Used CAD tools to create clean visualizations for assembly guides and integration with mechanical systems

##Tools & Technologies:

-PCB layout software: Altium Designer

-Thermal analysis & copper layering techniques

-EMI best practices for high-current, alternator-based systems

##Outcome:

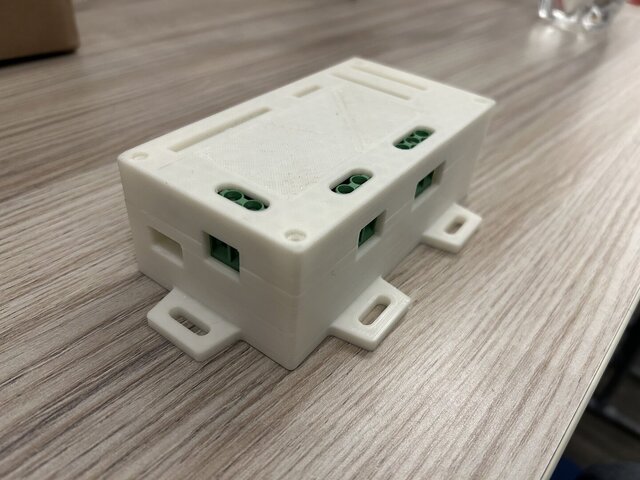

-Prototype successfully supported continuous 50 A operation in real-world PMA testing

-Board design achieved low EMI levels, enabling reliable motor control performance

-Finalized PCB offered excellent manufacturability, thermal resilience, and affordability

Published