Florida Commercial Pool Plumbing System in Fort Myers, FL

**Lighthouse Island Resort Commercial Pool Plumbing System**

1. **Executive Summary**

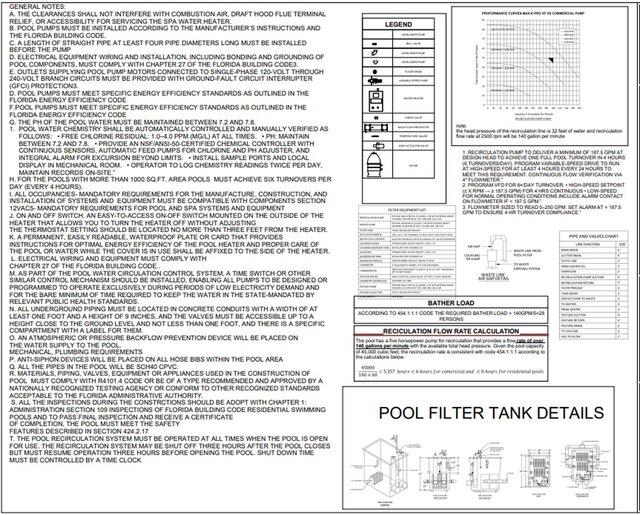

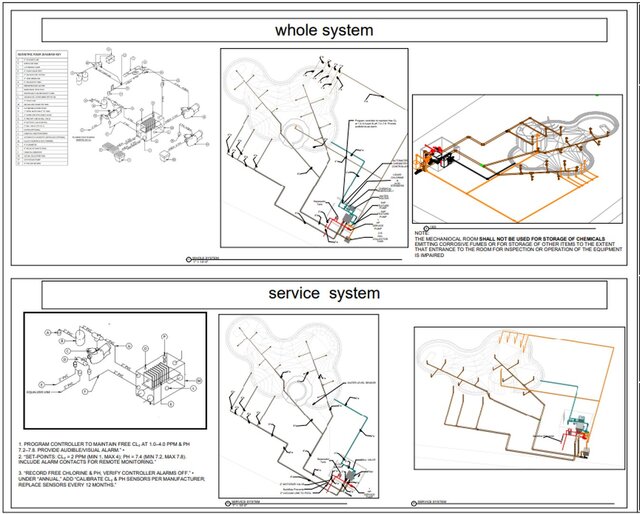

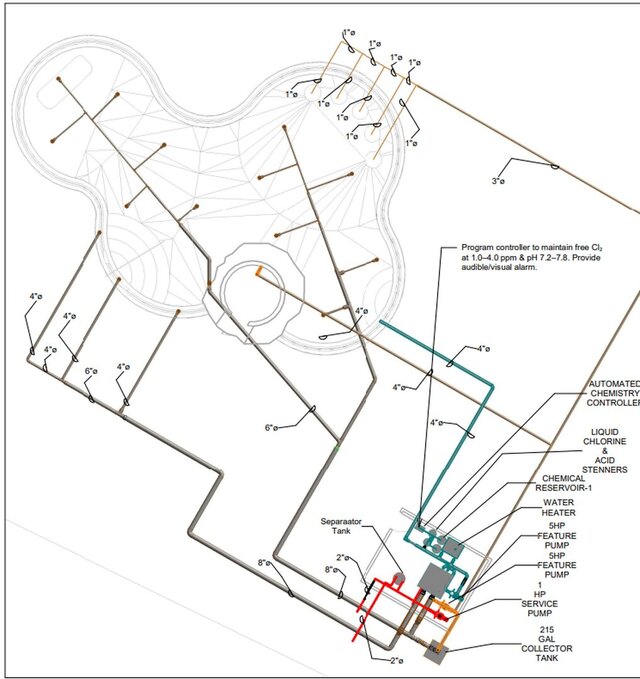

This project involves the design, specification, and installation of a commercial-grade swimming pool recirculation, filtration, and sanitation system for the Lighthouse Island Resort. The system is engineered to handle a pool volume of approximately 45,000 gallons, ensuring strict adherence to the Florida Building Code (FBC) and Florida Energy Efficiency Code. The design prioritizes water quality safety, energy efficiency, and reliable automation for maintenance.

2. **Technical Scope & System Specifications**

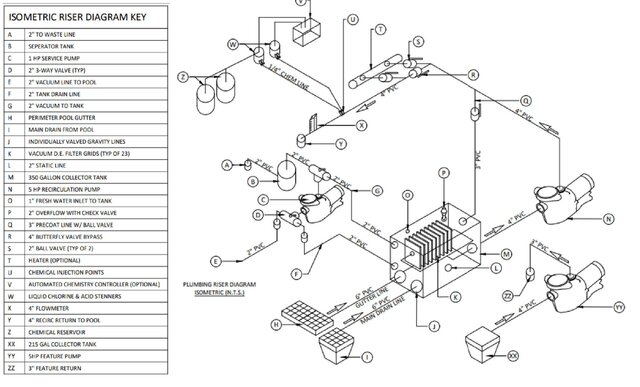

**A. Recirculation & Filtration System**

• Turnover Rate: The system is designed to achieve a mandatory 6 turnovers per day (one turnover every 4 hours).

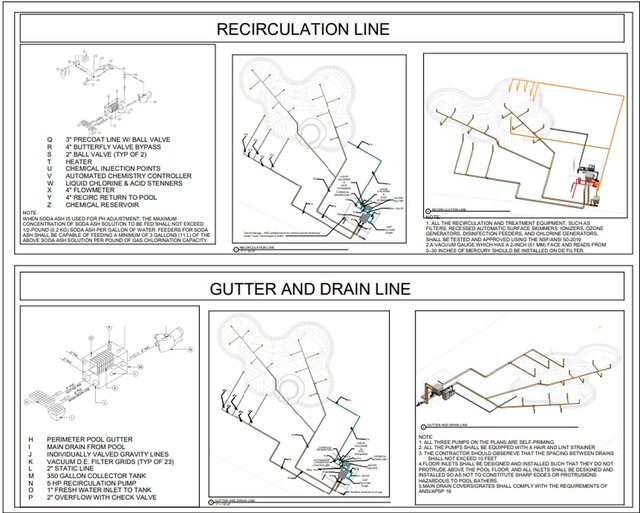

• Flow Rate Requirements: The primary recirculation loop is engineered for a minimum flow rate of 187.5 GPM at design head.

• Pump Equipment:

o Primary Pump: 5 HP Recirculation Pump (Self-priming).

o Feature Pump: 5 HP Feature Pump dedicated to water features.

o Variable Speed Drive (VFD): Programmed to run at high speed (approx. 187.5 GPM) for at least 4 hours daily to meet turnover mandates, utilizing low-speed operation for energy conservation during off-peak hours.

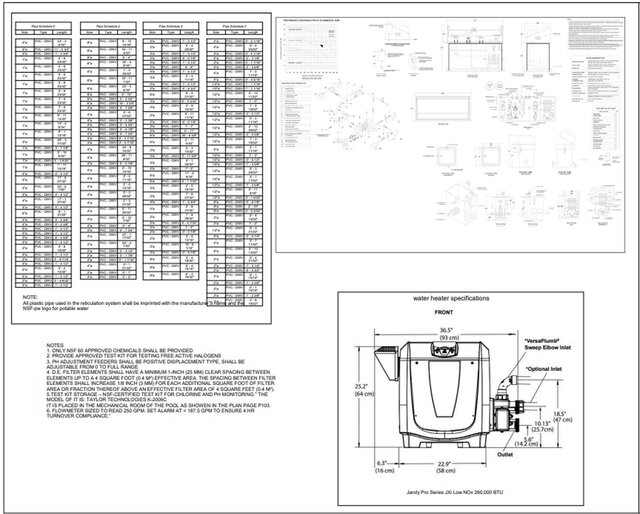

• Filtration: High-efficiency D.E. (Diatomaceous Earth) filter grids (Vacuum D.E. Filter) with a minimum 1-inch clear spacing between elements.

• Monitoring: Installation of a flowmeter (reading 0-250 GPM) with an integrated alarm set to trigger if flow drops below 187.5 GPM.

**B. Heating System**

• Heater Model: Jandy Pro Series JXi Low NOx 260,000 BTU.

• Installation: "VersaPlumb" configuration with sweep elbow inlets for hydraulic efficiency.

• Controls: External on/off switch accessible within 3 feet of the unit for safety disconnect without altering thermostat settings.

**C. Chemical Automation & Sanitation**

• Controller: NSF/ANSI-50 certified automated chemical controller with continuous sensors.

• Chemistry Targets:

o Free Chlorine: Automatically maintained between 1.0 – 4.0 PPM.

o pH: Automatically maintained between 7.2 – 7.8.

• Delivery: Automatic positive displacement feed pumps for liquid chlorine and acid (Stenners).

• Safety: Integrated visual/audible alarms for chemistry excursions and safety interlocks (flow switch).

• Testing: On-site testing via Taylor Technologies K-2006C kit for manual verification twice daily.

**D. Plumbing & Piping**

• Material: Schedule 40 (SCH40) CPVC for all pool piping.

• Layout:

o Underground piping encased in concrete conduits (12" width x 9" height).

o Perimeter pool gutter system with individually valved gravity lines.

o 350-gallon collector tank for surge management.

o 215-gallon collector tank for the feature system.

• Safety Features: Anti-siphon devices on hose bibs and atmospheric/pressure backflow preventers on water supply lines.

**3. Regulatory Compliance & Codes**

The installation adheres strictly to:

• Florida Building Code (Chapter 27 & Section 424.2.17): Electrical bonding, grounding, and safety features.

• Florida Energy Efficiency Code: Pump efficiency standards and timer controls.

• ANSI/APSP-16: Compliance for main drain covers and grates to prevent entrapment.

• NSF/ANSI 50-2019: Certification for all filtration, circulation, and treatment equipment.

**4. Operational Requirements**

• Bather Load: Calculated based on code 454.1.1.1 (approx. 140 GPM / 5-28 persons).

• Maintenance: * System must run continuously during open hours.

o Shut down permitted 3 hours after closing, resuming 3 hours before opening.

o Annual calibration of pH and Chlorine sensors required.