Microchannel Heat Exchanger with Non-Newtonian Fluids

# Numerical Simulation of Heat Transfer and Pressure Drop Characteristics for Non-Newtonian Fluids in Microchannel

## Introduction

Modern electronics are becoming smaller, faster and more powerful. As devices shrink, they also generate more heat in a compact space. Removing this heat efficiently is extremely important for the durability and performance of such systems.

Microchannel Heat Sinks (MCHS) have become one of the most effective cooling methods because their very small size allows heat to be absorbed quickly. Recently, researchers have found that using non-Newtonian fluids inside these microchannel improves cooling performance even more.

Non-Newtonian fluids are special liquids whose thickness (viscosity) changes depending on how fast they move. This unique behavior helps them carry heat more efficiently.

**Traditional microchannel sometimes suffer from problems like**:

- High pressure drop

- Uneven temperature distribution

To solve these issues, a design called Manifold Microchannel (MMC) was developed. MMCs use multiple small inlets and outlets to distribute the coolant more evenly.

**This project focuses on**:

- Modifying an existing MMC design

- Using a non-Newtonian fluid

- Running simulations to compare heat transfer and pressure drop

**Understanding how design changes improve cooling efficiency**

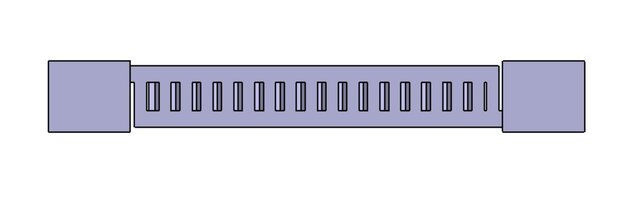

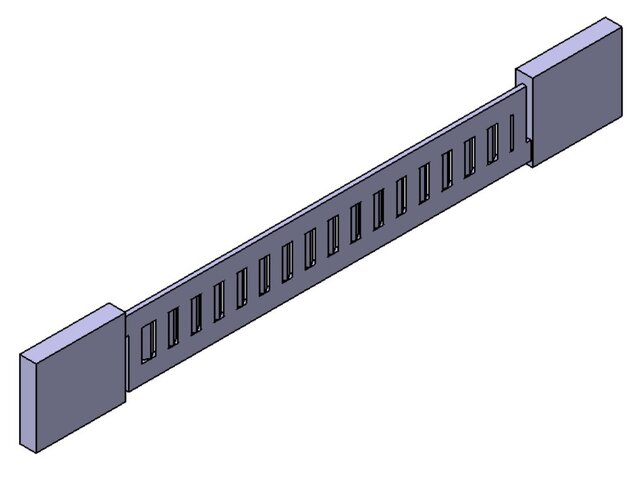

- Microchannel Heat Sink Design

- Microchannel Configuration

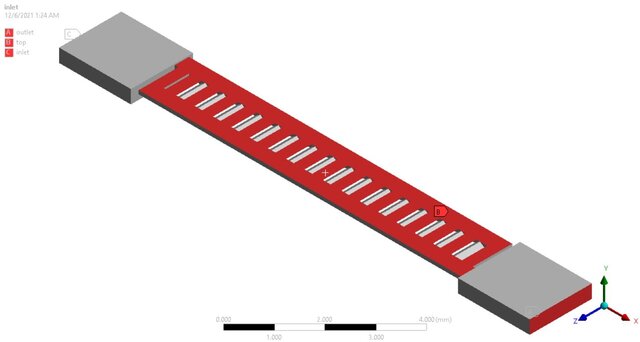

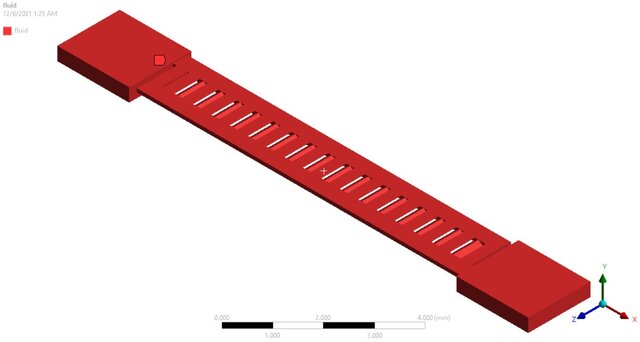

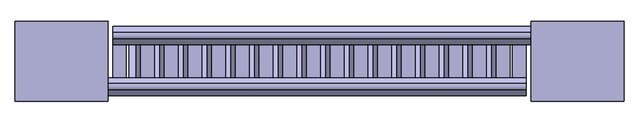

The design used in this project is based on the MMC proposed by Si-Ning Li et al. In this improved version:

- Manifolds (small channels) are arranged alternatively between the ribs.

- The ribs are given a fillet to smooth out fluid flow.

- The cross-section of channels is made triangular to increase contact surface area.

These changes help in:

- Better heat spreading

- More uniform coolant flow

- Lower resistance to movement (reduced pressure drop)

The design includes:

- 32 small transversal channels

- A very small hydraulic diameter

- A total compact volume, suitable for micro-electronics

The triangular shape increases contact between the coolant and the hot surface, and the alternating manifold placement helps the fluid spread more effectively over the heated area.

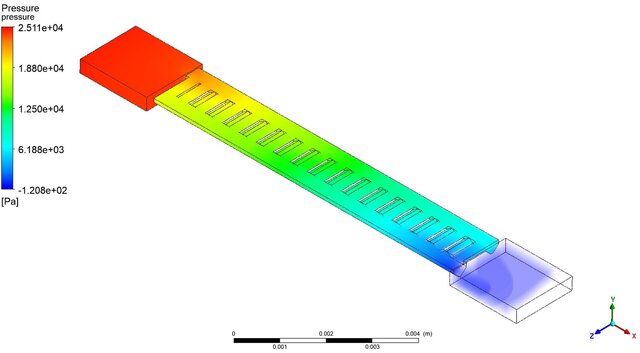

**Key concepts used in simulation**:

- Hydraulic diameter → represents the effective size of the channel

- Pressure drop → difference between inlet and outlet pressure

- Heat transfer coefficient → how well heat moves from wall to coolant

- Nusselt number → used to measure efficiency of cooling

- Thermal resistance → how difficult it is for heat to escape from the device

These values help us understand how efficient the microchannel is at cooling.

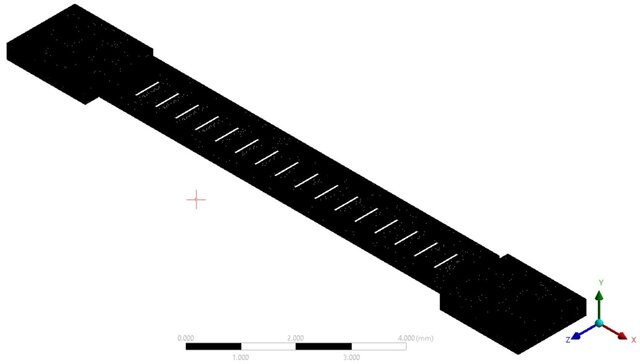

**Mesh Independence Test**

Before finalizing simulation results, several mesh sizes (computational grids) were tested to ensure accuracy. As the number of mesh elements increased, the results stopped changing significantly. Around 2 million mesh elements gave stable and reliable results, so this was chosen as the final mesh size.

**Model Validation**

- To check the accuracy of the design and simulation:

- Results were compared with a well-known reference paper.

- Temperature distribution and pressure behavior matched very closely.

This shows the simulation method and design setup are reliable.

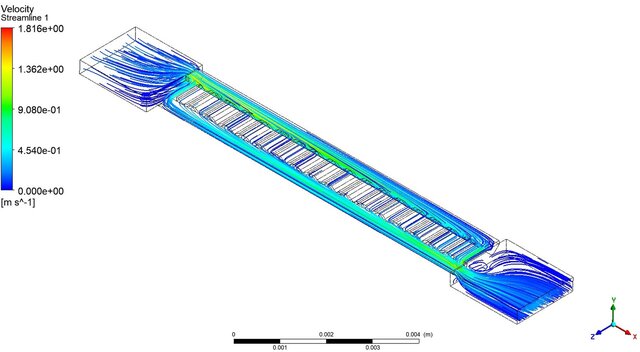

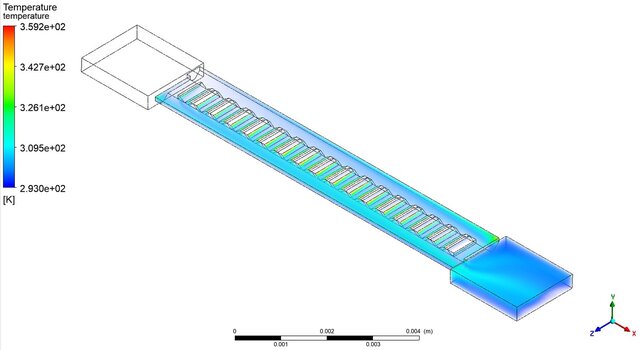

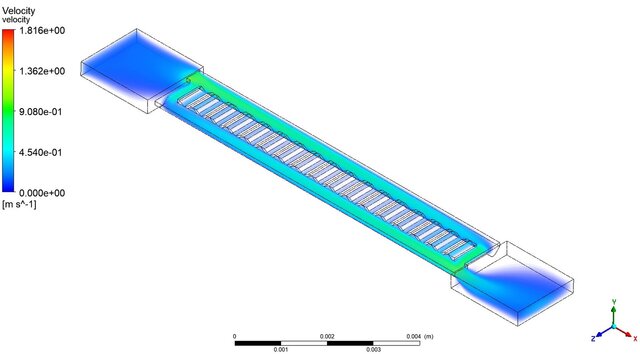

**Results and Discussion**

- Effect of Changing Manifold Geometry

- Several important findings were observed:

- Triangular microchannel gave much more uniform heat distribution.

- Alternate manifold placement increased coolant contact with hot surfaces.

- Filleted ribs allowed smoother flow, reducing pressure drop.

The modified design showed:

- Pressure drop reduced significantly (from around 0.6 bar to 0.24 bar)

- Heat absorption increased due to larger contact area

- Fluid flow became more streamlined

In simple words:

Changing the shape and arrangement made the microchannel cooler more efficient and easier for the fluid to flow through.

**Effect of Fluid and Material Selection**

Materials Tested:

- Copper

- Teflon polymer

- Using Teflon reduced weight but still maintained effective cooling.

Fluids Tested:

- Water

- Non-Newtonian fluid (Ethylene Glycol based)

**Key observations**:

- Water had lower pressure drop but limited temperature range

- Non-Newtonian fluid worked safely at higher temperatures

Thus, non-Newtonian fluids are better for electronics that operate at varying or high thermal loads.

**Conclusion**

This project successfully demonstrates that:

- Modifying the MMC design with alternate manifold placement and rib fillets improves cooling performance and increases thermal heat transfer.

- Using a non-Newtonian fluid significantly enhances heat removal.

- The pressure drop is reduced while heat transfer increases.

- The design is suitable for modern microelectronic cooling applications.

These findings are useful for industries working on cooling:

- Microprocessors

- Smartphones

- Laptops

- Nano-scale medical sensors

- Compact industrial components

Future work includes fabricating the modified MMC design and validating it with experimental tests.

Published