Method to Identify Metal Components for Additive Manufacturing

This project focused on developing a standardized method to identify and document metal components suitable for additive manufacturing.

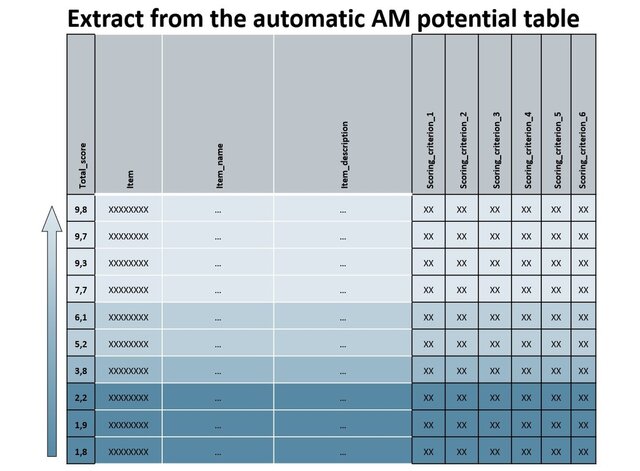

The outcome was an automated assessment tool for screening existing components, supported by a standardized template for individual evaluation and documentation. Within the scope of this work, components were identified, redesigned and prototypes produced, thereby demonstrating clear technical and economic advantages.

# Abstract

The mechanical engineering company is characterized by a high level of manufacturing depth and extensive expertise in conventional production processes. In contrast, metal additive manufacturing is not yet established, and it remains unclear which components are suitable for this technology. Furthermore, no standardized method exists for identifying suitable application cases. The objective of this work is to develop a standardized method for the identification and documentation of suitable metal components. This involves analyzing the technical and economic indicators and potentials based on the available data. Practical workflows and approaches from existing analysis methods are also incorporated into the development.

The outcome is an automated potential assessment tool for existing components, supporting efficient identification, as well as a standardized template for individual evaluation and documentation of application cases. Furthermore, as part of this work, components were identified, redesigned and prototypes produced, thereby demonstrating clear technical and economic advantages.