New York MEP plans for Renovation in Brooklyn

**Stamped MEP plans was delivered. **

There was many challenges in this project. This is how I overcame:

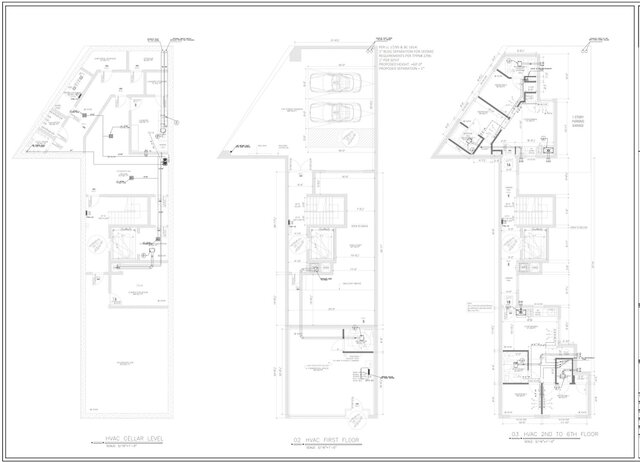

Performed full COMcheck/ENGERGY STAR modeling early; selects high-SEER heat pumps, ECM motors, and LED lighting; provides LL97 carbon-emission projections and mitigation pathways so the project stays under the cap.

Old building had no room for condensers, ducts, or sprinkler tanks; Used compact ductless VRF systems, low-profile air handlers, sidewall venting, or remote condensers on upper setbacks; coordinates tight shaft routing in Revit from the schematic phase

...

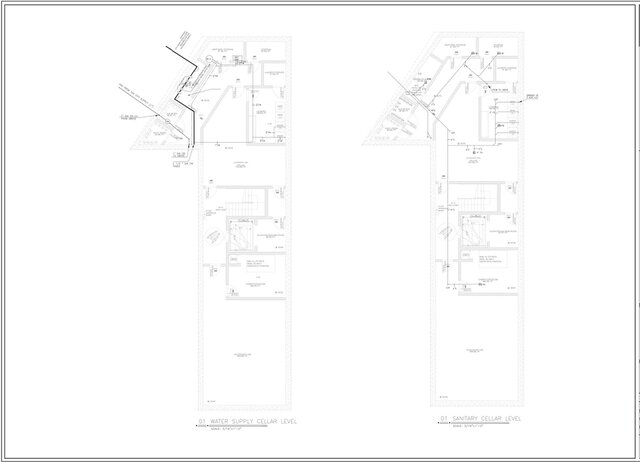

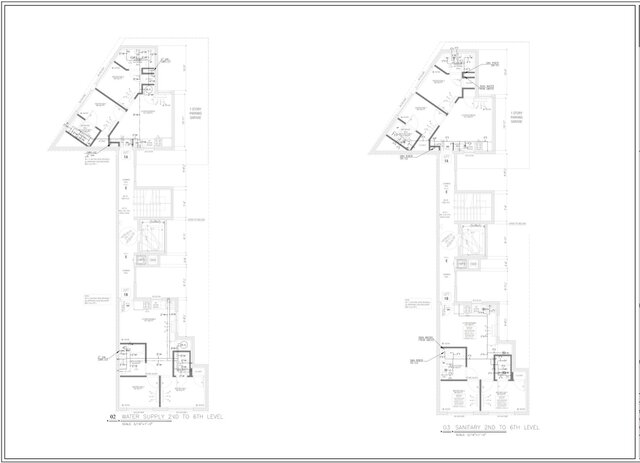

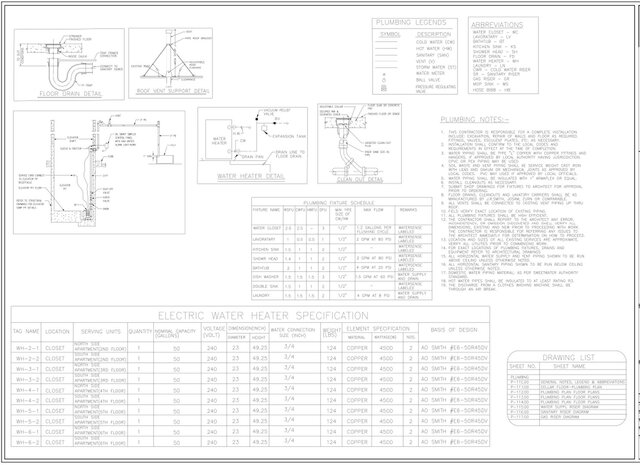

**Plumbing Scope Overview**

The project involved comprehensive updates to the building's infrastructure, designed to comply with local codes including the NYC Plumbing Code 2022.

Key aspects of the project included:

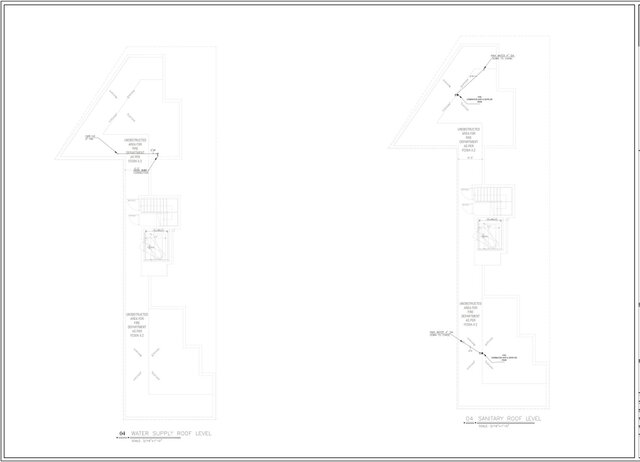

• Plumbing Systems: Installation of new domestic hot and cold water piping, sanitary pipes, and vent systems. Specific materials and installation methods are detailed, such as using ASTM B 88 Type 'L' hard copper for water piping and PVC-U type pipes for sanitary systems Non-freeze anti-siphon automatic draining wall faucets are specified for external taps.

• Fixtures and Equipment: The plans include a schedule for various plumbing fixtures like water closets, lavatories, kitchen sinks, showers, and floor drains, specifying minimum pipe sizes and water flow rates.

• Water Management: The design accounts for water pressure regulation if pressure exceeds 80 PSI and includes provisions for backflow prevention and shut-off/drain valves at strategic locations.

• Insulation and Protection: Domestic water piping above grade was required to be insulated with engineered polymer foam or fiberglass, and all copper piping must be protected against contact with dissimilar metals and masonry. All external pipes required R-4 insulation against freezing .

The plumbing system detailed in the plans was focused on domestic water, sanitary, and vent systems.

**Domestic Water System**

The domestic water system uses ASTM B 88 Type 'L' hard copper tube with wrot copper fittings. Joints are soldered or pressure sealed.

• Piping Route: Hot and cold water pipes pass over the ceiling, placed near the wall, and are fixed every 4 feet. No pipes pass above the living room.

• Insulation: Piping above grade (except exposed connections) is insulated with engineered polymer foam or fiberglass insulation. Insulation, jackets, and sealers must have a flame spread rating not exceeding 25 and a smoke developed rating not exceeding 50 when tested per ASTM E 84. All external pipes must have R-4 insulation against freezing.

• Fittings and Valves: Shut-off valves must be full port, ball type, installed where accessible for service. Drain valves are provided at all low points for complete drainage of the systems. The external taps are ZIS45 non-freeze anti-siphon automatic draining wall faucet type.

• Protection: Copper piping is protected from contact with dissimilar metals using copper or copper-plated hangers, supports, and clips. When carried on iron trapeze hangers, an electrolytic isolation material is used. For piping through or against masonry, a heavy coating of asphaltic enamel and asphalt-saturated felt is used.

• Pressure: A pressure regulator must be installed if water pressure exceeds 80 PSI. Normal minimum pressure at the main is 80 PSI, with a regulated pressure of 68 PSI.

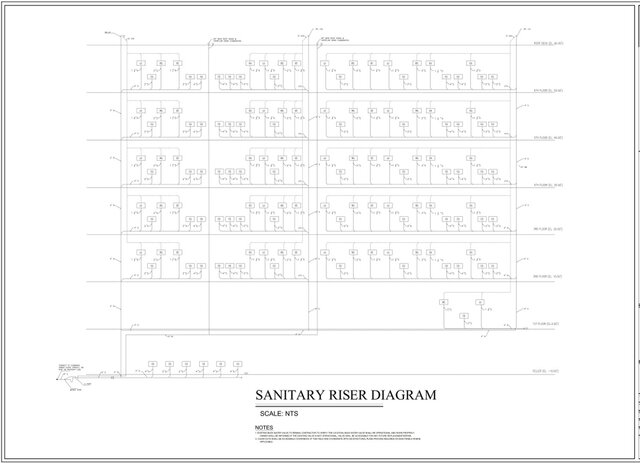

**Sanitary and Vent System**

All sanitary pipes should be PVC-U type. The slopes of the sanitary pipes are shown in the sanitary plan.

• Pipe Material Schedule:

o 3" and smaller service uses WT.CL. no-hub pipe and fittings.

o 4" and larger storm service uses WT. C.L. hub and spigot pipe and fittings.

• Vent Termination: All plumbing vents terminate to the building's main vent line.

• Cleanouts: All plumbing clean-outs are installed where readily accessible and coordinated with equipment and cabinets.

• Sloping: Pipes require a 1/2" slope per foot.

**Fixture Schedule**

The plans provide a plumbing fixture schedule detailing water supply fixture units (WSFU), minimum pipe sizes, and drain fixture units (DFU).

**The project adheres to the Residential Code of New York State 2020 and the NYC Plumbing Code 2022.**

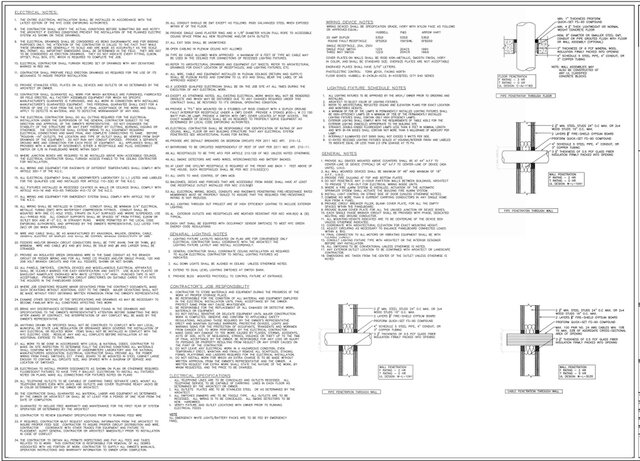

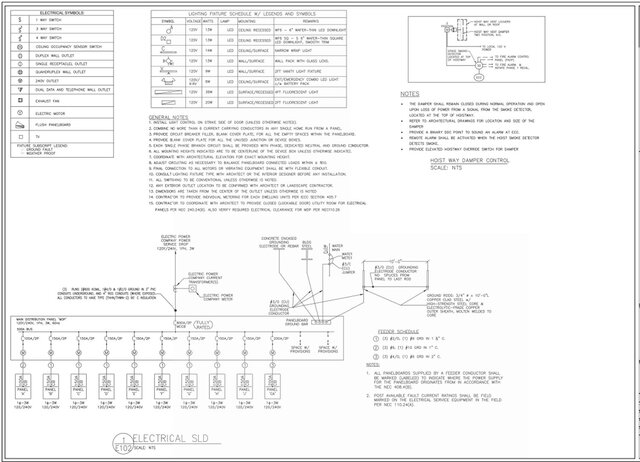

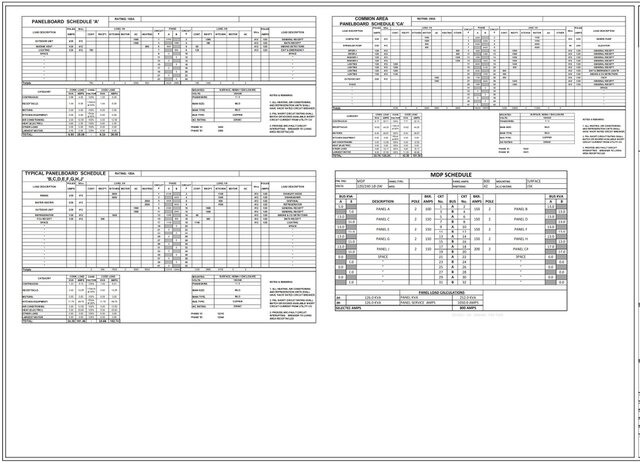

**Electrical**

The electrical plans for the renovation project at 8 Grand Avenue, Brooklyn, NY 11205 detail the installation, alteration, and repair of the electrical wiring system, including power distribution and lighting. All work must conform to the CSA C22. 1-21 Canadian Electrical Code (25th Edition) and local NYC jurisdiction requirements.

**General Electrical Requirements**

• **Materials & Equipment**: All equipment must be new (unless noted otherwise) and bear the Underwriter’s Laboratories (UL) label. Aluminum conduit and nonmetallic conduit above grade are not permitted.

• **Conductors**: All conductors must be copper, with a minimum size of #12 AWG for general circuits and #2 AWG for all conductors. Feeders, however, are specified as aluminum (THW or THHN/THWN insulation). A color code must be used throughout the wiring as per NEC requirements.

• **Circuitry**: Branch circuitry and feeders are to be run concealed, with a minimum conduit size of 3/4" EMT. Final connections to motors or vibrating equipment must use flexible conduit.

• **Grounding**: Grounding must be provided for all devices as per NEC requirements, and all receptacle circuits must contain a #12 insulated ground conductor. GFCI (Ground-Fault Circuit Interrupter) outlets are required in wet locations.

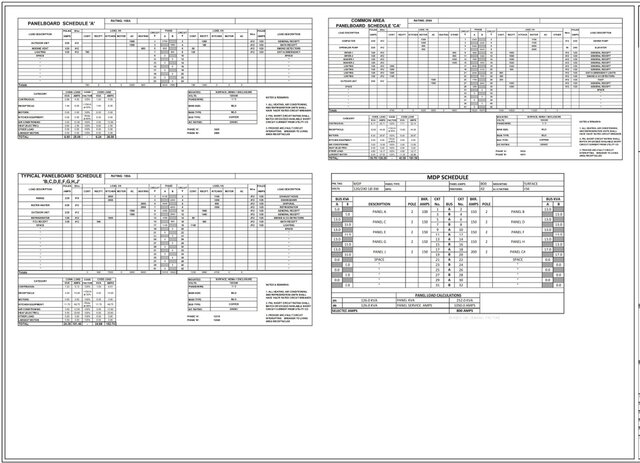

• **Panelboards**: The contractor is responsible for balancing all panelboards across phases. The plans include a riser diagram and panel schedules for PB-301, PB-308, and an Outdoor Panel Box.

• **Coordination & Testing**: The electrical contractor must coordinate work with all other trades to avoid conflicts and perform final testing to ensure all circuits are free of short circuits at the time of inspection.

Lighting and Outlets

• **Lighting Fixtures**: All new lighting fixtures are installed complete with lamps as per the lighting fixture schedule, which includes recessed LED ceiling lights and wall-mounted fixtures. Fixture colors are to be selected by the architect.

• **Switches & Receptacles**: Where multiple devices of the same voltage are grouped, a ganged plate is used; different voltages must be separated by 6". Back-to-back outlets are offset by a minimum of 6" horizontally.

• **Outdoor Installations**: All panel boards, switches, and receptacles installed on the roof must be waterproof, protected against weather, and run through conduit.

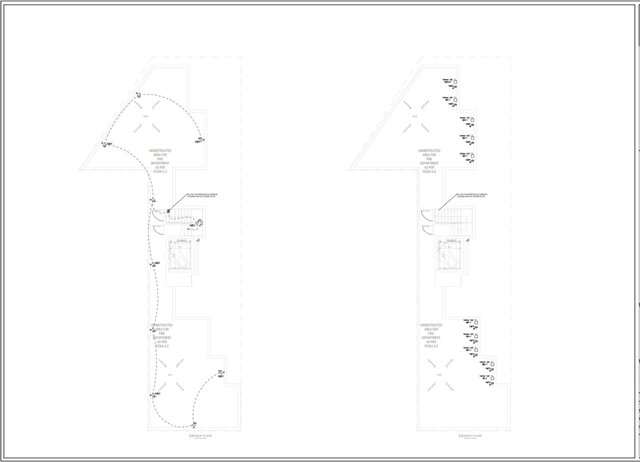

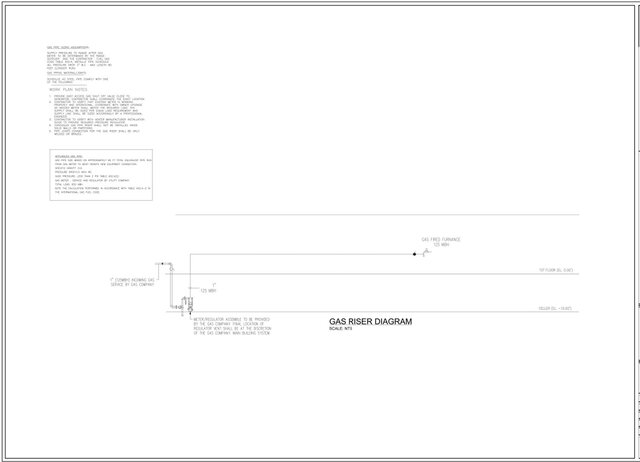

**HVAC**

The HVAC system detailed in the plans is a renovation project that includes exhaust fans, ductwork, grilles, diffusers, and thermostat wiring. The work must comply with local codes, including ASHRAE Standard, National Electric Code, and State Mechanical Code.

Published