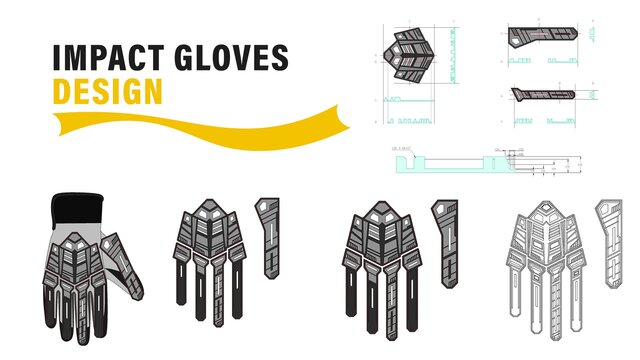

Industrial Impact Glove Guards | Ergonomic DFM Design

# High-Performance Impact Glove Protection Design

## Project Overview

This project focuses on the **advanced surfacing** and **mechanical design** of dorsal impact guards for industrial safety gloves. The design balances maximum impact dissipation with the essential requirement for hand dexterity and user comfort.

## Technical Design & DFM Features

The guards are engineered specifically for high-volume **TPR (Thermoplastic Rubber)** injection molding.

- **Anatomic Flex-Zones:** Segmented geometry modeled to follow the hand’s natural movement, ensuring full range of motion at the knuckles and finger joints.

- **Impact Dissipation:** Internal ribbing and variable thickness zones designed to meet **ANSI/ISEA 138** impact protection standards.

- **DFM Optimization:** - Precise **draft angles** for clean mold release.

- Uniform wall thickness to prevent sink marks in TPR.

- Optimized for cost-effective tooling and rapid cycle times.

- **Ergonomics:** Sleek, low-profile design to reduce snagging in tight workspaces while maintaining high-visibility aesthetics.

## Tools & Deliverables

- **Primary CAD Software:** **SolidWorks** (Complex Surface Modeling)

- **Visualization:** Photorealistic material renders in **KeyShot**.

- **Deliverables:** Production-ready **STEP** files, native **SolidWorks** files, and 2D technical specifications.

This project demonstrates my expertise in combining ergonomic user requirements with rigorous manufacturing standards.