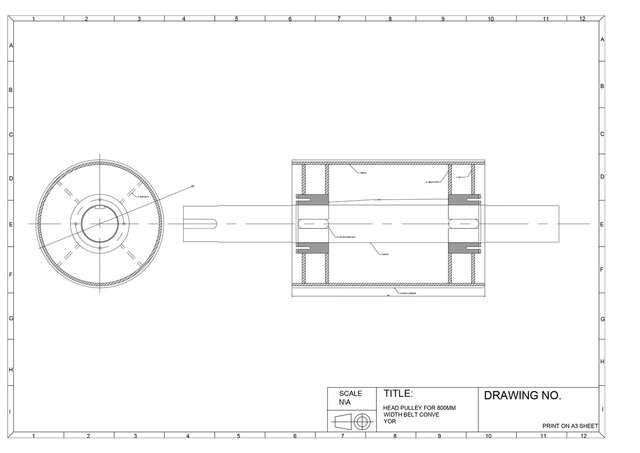

HEAD PULLEY FOR 800MM WIDTH BELT CONVEYOR

A belt conveyor pulley is a critical mechanical component used to drive and redirect the conveyor belt. For a system with 800 mm belt width, the pulleys must be appropriately sized and engineered to support the load, belt tension, and operational environment.

🔹 Types of Pulley Used:

Drive Pulley: Provides the driving force to move the belt.

Tail Pulley: Located at the return end; helps in belt tracking.

Snub Pulley: Increases belt wrap angle on drive pulley for better grip.

Take-up Pulley: Maintains belt tension and absorbs elongation.

🔹 Pulley Dimensions (Typical for 800 mm Belt):

Face Width: ~950 to 1000 mm (approx. 1.15–1.2 × belt width)

Pulley Diameter: Depends on application, typically ranges from 315 mm to 700 mm

Shaft Diameter: Designed based on load and torque (e.g., ~100–220 mm)

🔹 Construction Materials:

Shell: 600NB shameless SCH-80 pipe (Mild Steel)

Shaft: Carbon Steel (EN8/EN9).

Lagging (for drive pulley): Rubber or ceramic for better traction.

🔹 Design Considerations:

Belt Speed: Typically 1.5 – 3.5 m/s

Load Capacity: Depends on bulk density and conveyor inclination.

Pulley Bearing Type: Spherical roller bearings with adaptor sleeve for heavy-duty use.

Balancing: Static and dynamic balancing to minimize vibration.

🔹 Applications:

Used in industries like mining, cement, steel, ports, and power plants for transporting bulk materials like coal, limestone, and iron ore.