Design of a Double Wishbone Suspension for High-Performance Sports Vehicles

Project Overview

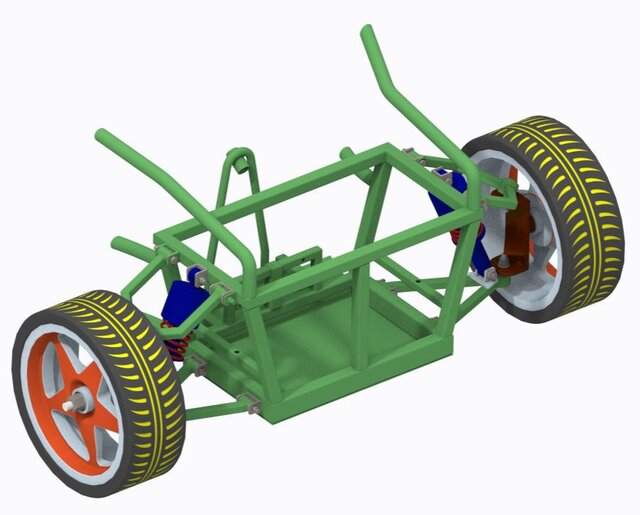

Our company engineered a double wishbone suspension system, also known as an independent or A-arm suspension, for a new line of high-performance sports vehicles. The system was designed to provide exceptional handling, stability, and ride comfort while enduring the extreme conditions of high-speed driving. The project encompassed the full design lifecycle, including concept development, kinematic and load calculations, finite element analysis (FEA), geometric dimensioning and tolerancing (GD&T), and the creation of detailed manufacturing drawings. This case study highlights our expertise in delivering advanced automotive solutions tailored for superior vehicle dynamics.

Concept Design

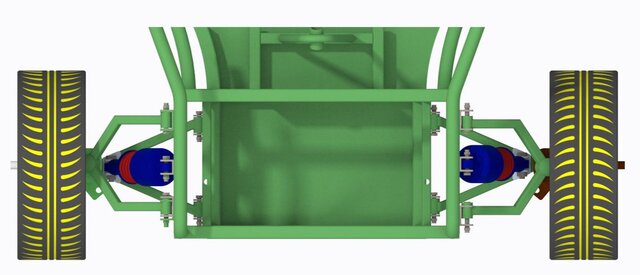

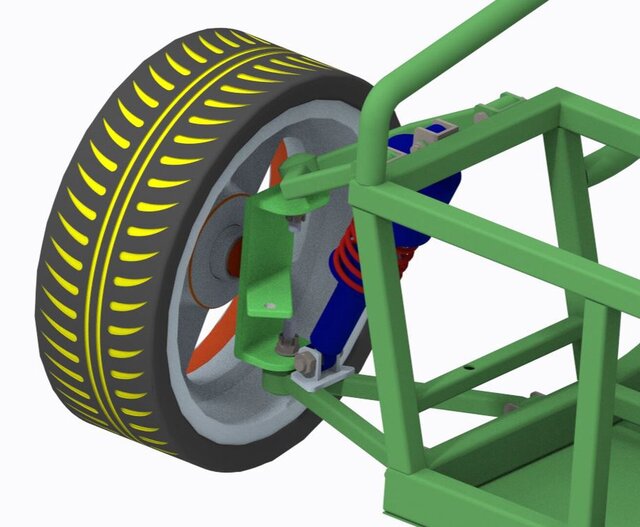

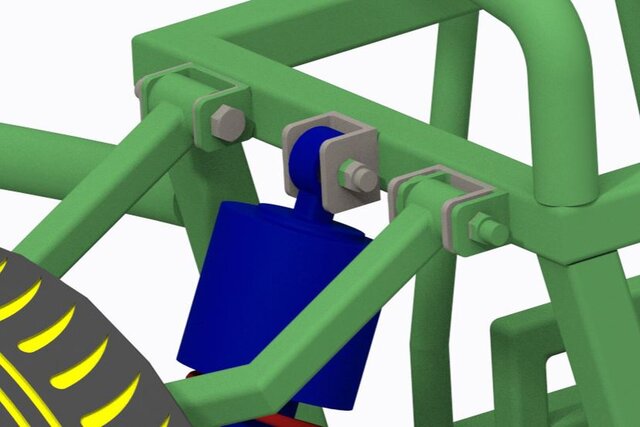

The double wishbone suspension is renowned for its ability to maintain precise wheel control, making it ideal for sports cars. Our design featured upper and lower wishbones connected to the chassis and wheel upright, enabling independent wheel movement to enhance handling and reduce unsprung weight.

Key components included:

• Upper and Lower Wishbones: Constructed from AISI 4130 chromoly steel for high strength and low weight.

• Upright: Designed to integrate the wheel hub, brake caliper, and steering components, ensuring rigidity.

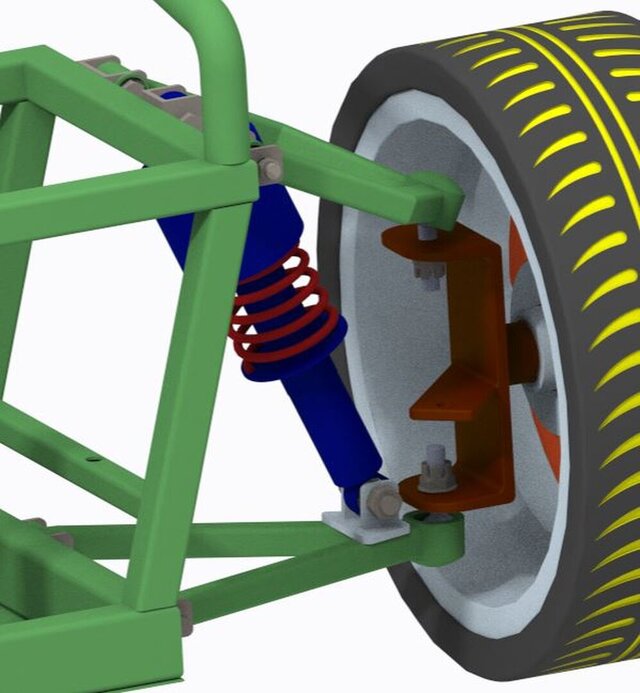

• Coil Springs and Dampers: Tuned for a 1500 kg vehicle to optimize ride height and damping.

• Anti-Roll Bar: Incorporated to minimize body roll during cornering.

The design prioritized performance, ensuring compatibility with the vehicle’s chassis and steering systems, as detailed in automotive engineering principles (Automotive Suspension Design).

Relevant Calculations

Critical calculations ensured the suspension met performance targets:

• Kinematic Analysis: Camber, caster (4.43°), and toe angles were optimized for tire contact, with negative camber enhancing cornering grip.

• Load Calculations: For a 1500 kg vehicle, each front wheel supported ~750 kg, with dynamic loads (2105.42 N per wheel) calculated for acceleration, braking, and cornering.

• Spring Rate Selection: Front springs (15 N/mm) and rear springs (12 N/mm) were chosen, yielding ride frequencies of 2.34 Hz (front) and 1.82 Hz (rear), balancing comfort and handling (Design and Calculation).

These calculations guided component sizing and system integration.

Finite Element Analysis (FEA)

FEA, performed using ANSYS, validated component durability:

• Wishbone Analysis: Under peak loads, maximum stress was 300 MPa, below the 415 MPa yield strength of AISI 4130, with deformation <1 mm.

• Upright Analysis: Maximum stress was 250 MPa, with a safety factor of 1.6.

• Fatigue Analysis: Components were designed for >1 million cycles, ensuring long-term reliability.

FEA results drove reinforcements at high-stress areas, as supported by research (Double Wishbone Analysis).

Manufacturing Drawings Creation

Detailed drawings were produced in CATIA V5, specifying:

• Materials: AISI 4130 chromoly steel with heat treatment for durability.

• Dimensions and Tolerances: Tight tolerances for interchangeability.

• Surface Finishes: Applied to wear-prone areas for corrosion resistance.

These drawings streamlined fabrication, ensuring cost-effective production (Design and Calculation).

Key Technical Challenges

The project faced significant challenges:

• Stiffness vs. Compliance: Achieving high-speed stability while maintaining comfort required precise spring and damper tuning.

• Space Constraints: Inboard mounting of springs and dampers addressed limited chassis space.

• Durability: High loads and temperatures were mitigated through material selection and FEA validation.

These challenges were overcome through iterative design and simulation.

Our Company’s Contribution

Our team delivered exceptional value:

• Advanced Engineering: Utilized CATIA for modelling and ANSYS for FEA, enabling virtual optimization.

• Material Expertise: Selected AISI 4130 for optimal strength-to-weight ratio.

• Collaboration: Partnered with manufacturing teams to ensure producibility and cost-efficiency.

• Performance Focus: Fine-tuned the system for superior handling, setting a benchmark for sports car dynamics.

Additional Considerations

• Testing and Validation: Post-manufacturing tests confirmed kinematic accuracy and load-bearing capacity, aligning with design goals.

• Integration: The suspension seamlessly integrated with steering and braking systems, enhancing overall vehicle performance.

Conclusion

This project showcases our ability to design a high-performance double wishbone suspension system from concept to production. By leveraging advanced tools, rigorous analysis, and collaborative expertise, we delivered a solution that enhances handling, stability, and driver experience, reinforcing our leadership in automotive engineering.