Design of a Customized Scissor Lift with Platform

Project Overview

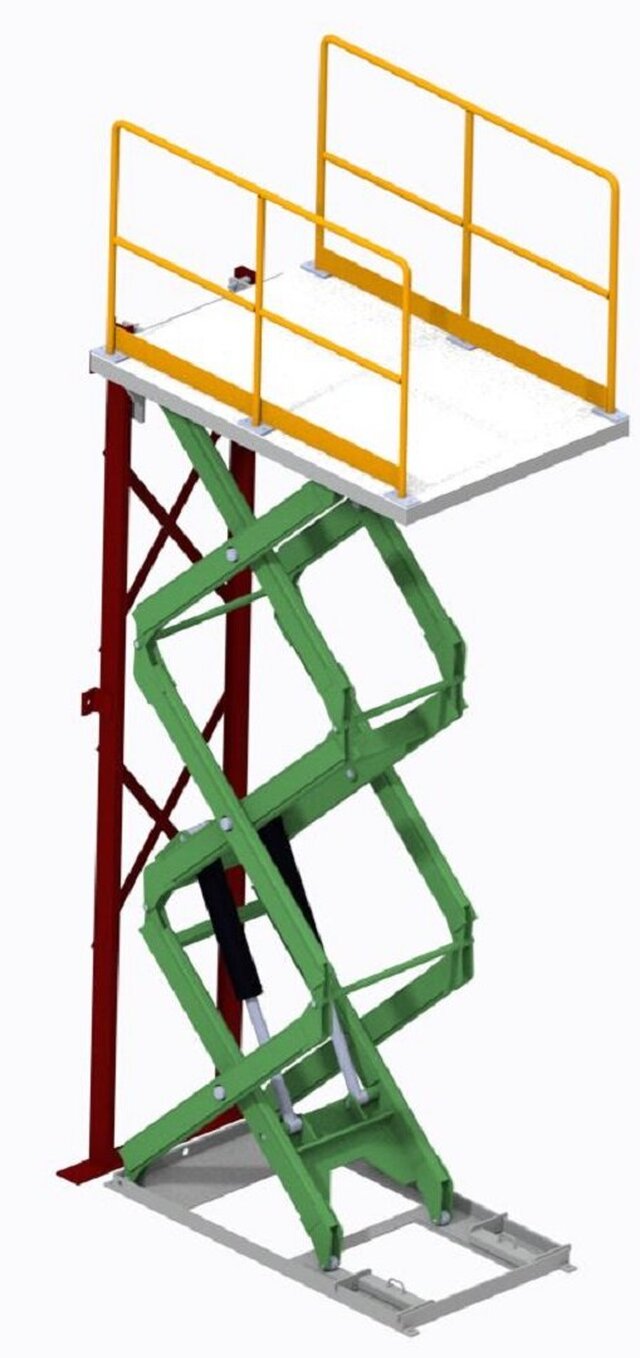

Our company engineered a bespoke Hydraulic scissor lift for a manufacturing plant, designed to elevate 1000 kg of heavy machinery components to a height of 5 meters. The lift featured a 2m x 2m platform and was tailored for indoor use, prioritizing safety, stability, and efficiency. The project spanned concept design, load and kinematic calculations, finite element analysis (FEA), geometric dimensioning and tolerancing (GD&T), and manufacturing drawings creation, ensuring compliance with standards like ISO 16368 for elevating work platforms.

Concept Design

The design process began with a detailed analysis of the client’s needs, leading to a double-stage scissor lift configuration to achieve the 5-meter height while maintaining a compact footprint. Key components included:

• Platform and Base: Constructed from high-strength steel for durability.

• Scissor Arms: Designed to handle significant loads with minimal deflection.

• Hydraulic Actuators: Provided precise, energy-efficient lifting.

• Control System: Equipped with emergency stop, load sensors, and operator-friendly interfaces.

Modeled in Creo, the design ensured seamless integration into the client’s workflow, emphasizing safety and ease of use.

Relevant Calculations

Critical calculations validated the lift’s performance:

• Load Assessment: Total load of 1300 kg (1000 kg payload + 300 kg structure).

• Actuator Force: For a 4:1 mechanical advantage, the required force was (1300 kg × 9.8 m/s²) / 4 ≈ 3175 N, guiding actuator selection. Our Team involved in selection of actuator with supplier for this requirement based on specifications derived from calculations.

• Stability Analysis: Ensured the center of gravity remained within the base footprint at maximum height, preventing tipping.

These calculations, informed by scissor lift mechanics (Scissor Lift Principles), confirmed the design’s feasibility.

Finite Element Analysis (FEA)

FEA, conducted using ANSYS, assessed structural integrity:

• Stress Analysis: Maximum stress in scissor arms was 250 MPa, below the 400 MPa yield strength of high-strength steel, yielding a safety factor of 1.6.

• Deflection: Platform deflection was limited to 2 mm, ensuring stability.

• Fatigue: Components were designed for over 500,000 cycles, supporting long-term reliability.

FEA results drove optimizations, such as reinforcing pivot joints, aligning with industry practices (FEA Analysis).

Manufacturing Drawings Creation

Detailed drawings, created in Creo, guided fabrication:

• Assembly Drawings: Illustrated component integration.

• Part Drawings: Specified dimensions, high-strength steel, and corrosion-resistant coatings.

• Bill of Materials (BOM): Listed all components for procurement.

The drawings optimized production efficiency and cost, as noted in design principles (DFM Principles).

Key Technical Challenges

The project faced several challenges:

• Stability at Height: Ensuring stability at 5 meters required precise load distribution and a robust base design.

• Weight Optimization: Balancing strength with lightweight materials to enhance portability.

• Safety Integration: Incorporating features like descent guards and release locks to meet ISO 16368 standards.

These were addressed through iterative FEA, material selection, and safety-focused design.

Our Company’s Contribution

Our team’s expertise was pivotal:

• Advanced Engineering: Leveraged Creo and ANSYS for design and validation.

• Client Collaboration: Worked closely with the client to refine specifications.

• Safety Focus: Integrated features like load sensors and emergency stops, ensuring compliance.

• Manufacturability: Delivered drawings that streamlined production, reducing costs.

Our rigorous approach ensured a solution that met the client’s unique needs.

Additional Considerations

• Operator Safety: Included guardrails and anti-skid plates on the platform, aligning with OSHA guidelines.

• Sustainability: Optimized actuator efficiency to minimize energy consumption.

Conclusion

This project showcases our ability to deliver customized scissor lifts for specialized industrial applications. By integrating advanced design, rigorous analysis, and client collaboration, we provided a reliable, safe, and efficient solution that enhanced the client’s operations, reinforcing our expertise in bespoke engineering.