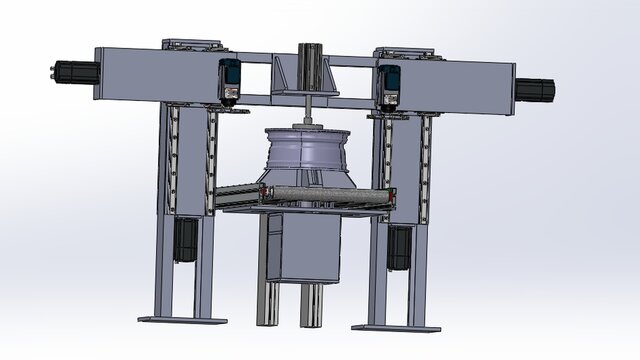

Deburring of the rim

This is a specially designed 3-axis deburring system developed for removing burrs formed after the molding or casting process of aluminum or steel rims. The system begins by accurately positioning the rim in a fixed station using a clamping or centering mechanism. Once the rim is securely held in place, the deburring process is carried out with precision using tools mounted on a 3-axis robotic arm or CNC-controlled platform.

Thanks to its three-axis motion capability, the system can reach complex geometries and inner/outer edges of the rim, ensuring that all unwanted burrs, sharp edges, or flash are effectively removed. This not only improves the surface quality and appearance of the rim but also ensures safety in handling and compatibility with subsequent processes such as painting or assembly.

This automated solution increases production efficiency, reduces manual labor, and provides consistent deburring quality for every rim.

Published