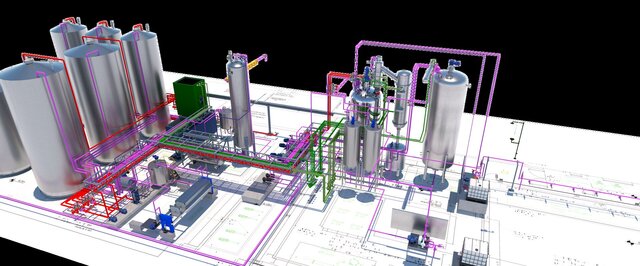

Chemical Plant - Multi-process System

This fully integrated chemical refining plant was designed to support a wide range of industrial reactions and separation processes. It includes high-performance reactors with thermal fluid heating (up to 250 °C), cold water cooling, vacuum operation, inertization, and condensation systems. Independent dosing units ensure precise and fractional chemical addition.

🔧 Key Features

- Thermal fluid heating and cold water cooling

- Vacuum, inert gas, and condensation systems

- Modular reactors for diverse chemical reactions

- Independent and accurate chemical dosing systems

- Engineered for continuous and batch operations

🧪 Supported Processes

- Acid-base reactions and dilutions

- Polymerization, esterification, hydroxylation, epoxidation

- Oxidative and adsorptive oil clarification

- Hydrolysis, distillation, and vacuum drying

- Filtration and oil deodorization

🏗️ Engineering Scope

- Full 3D design and rendering of infrastructure

- Piperack layout, piping, structural steel, and masonry

- Based on architectural plans, P&ID, and isometric drawings