Centrifugal Compressor & Turbine Design

# Turbomachinery

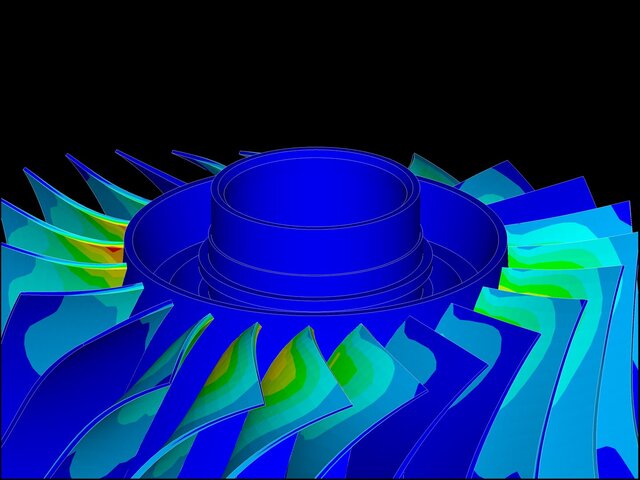

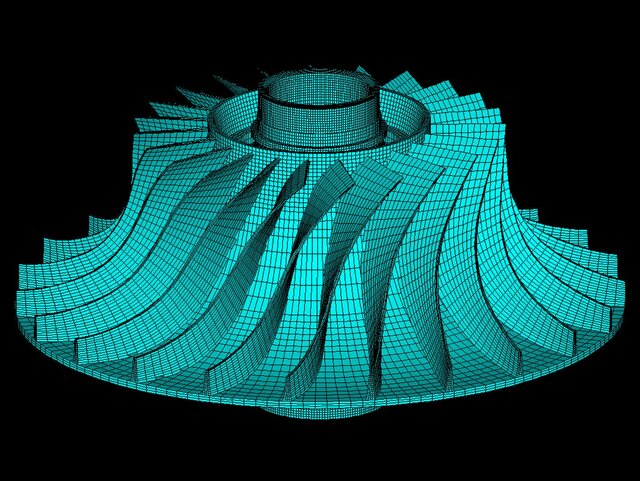

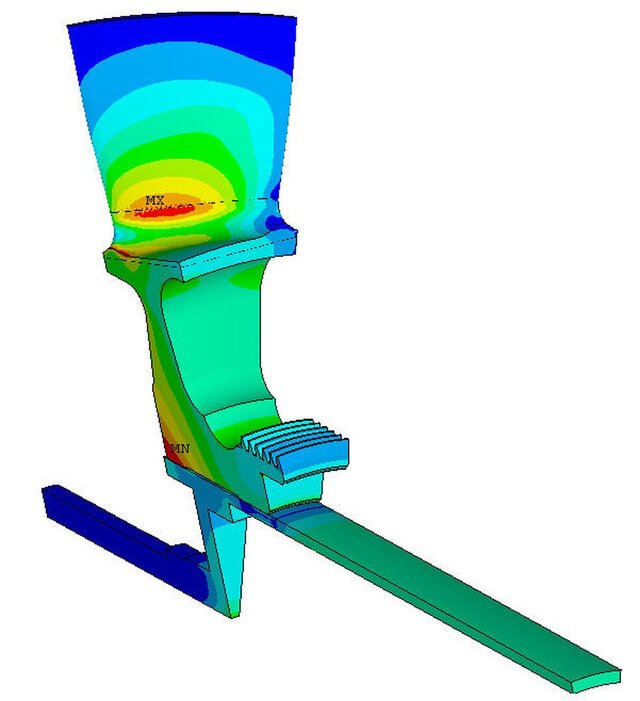

**Centrifugal compressor** design involves optimizing aerodynamic, thermodynamic, and mechanical aspects to achieve high efficiency, pressure ratios, and reliability. The design process begins with defining performance requirements, including mass flow rate, pressure ratio, and rotational speed. The impeller, a key component, is designed with carefully contoured blades to maximize energy transfer from the rotating shaft to the working fluid while minimizing losses. Diffusers, either vaned or vaneless, facilitate pressure recovery by decelerating the high-velocity flow exiting the impeller. The volute or collector is shaped to ensure uniform flow distribution and minimize pressure losses. CFD) and FEA play critical roles in refining the aerodynamics and structural integrity of the components. Additionally, material selection, thermal management, and bearing system design are crucial to ensuring durability and high-speed operation.

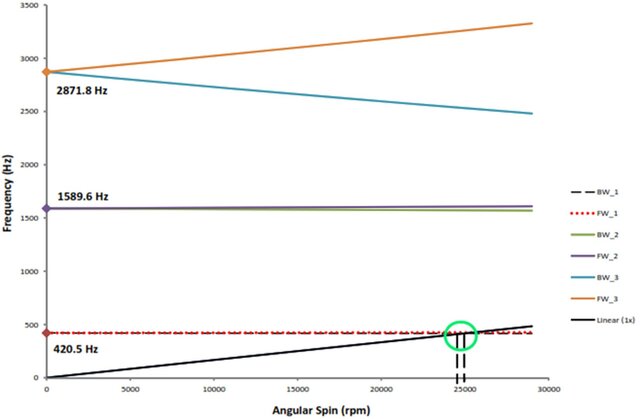

**Rotordynamics** is a critical aspect of centrifugal compressor design, directly influencing the machine’s stability, reliability, and operational life. A comprehensive rotordynamic analysis ensures that the rotating assembly operates safely within the allowable speed range, avoiding resonance and excessive vibration.

Key to this analysis is the identification and characterization of forward and backward whirl modes. Forward whirl occurs when the precession of the rotor matches the direction of rotation, typically resulting in higher critical speeds and is more common in well-balanced systems. In contrast, backward whirl involves precession opposite to the rotation direction and can be induced by anisotropic bearing stiffness, misalignments, or structural asymmetries.

Both whirl modes are assessed during **Campbell diagram** construction and stability analyses. Their accurate prediction is essential for setting safe operational limits and designing the bearing and support system to suppress instability. Neglecting these dynamic behaviors can lead to premature bearing wear, shaft fatigue, or even catastrophic failure under certain conditions.

By addressing forward and backward whirls through detailed rotordynamic modeling I can optimize the compressor design for long-term performance and structural integrity across the full speed envelope.

The original compressor design is also shown with a chipped blade after excessive plastic deformation at blade tip.

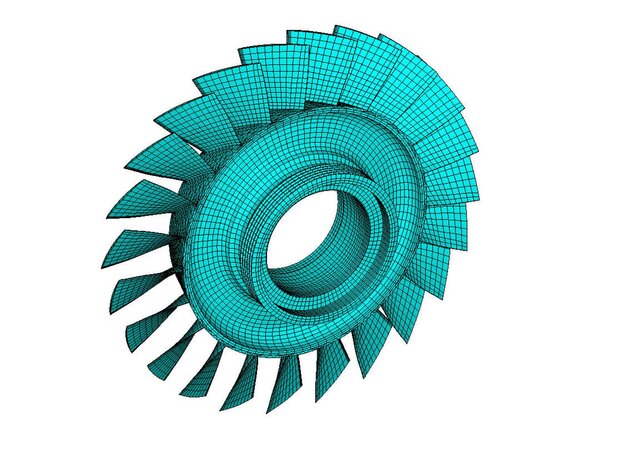

In axial flow turbine design, rotordynamic analysis becomes equally vital, particularly due to the use of blisks (bladed disks), which integrate the rotor disk and blades into a single component. This integration reduces weight and improves aerodynamic efficiency but introduces unique challenges in stress distribution. Stress concentrations are typically observed at the blade roots, where cyclic loading and high centrifugal forces converge. Detailed **FEA** with fine mesh resolution in these critical regions is necessary to capture localized stresses accurately and prevent fatigue failures. The blisk's dynamic behavior must be evaluated in conjunction with its material properties, damping characteristics, and boundary conditions to ensure robust performance under high-speed operational regimes.