Case Study: Steel Structure Design for Modular Skids

Introduction

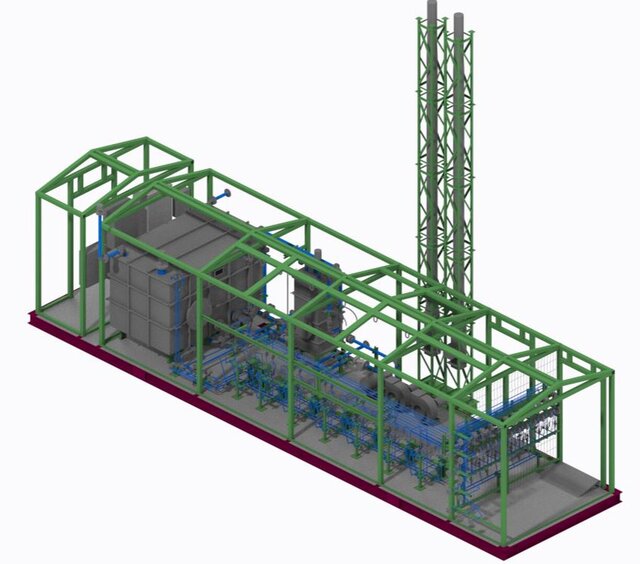

In the rapidly evolving industrial sector, modular skids have become a cornerstone for efficient and adaptable infrastructure solutions. Our team has excelled in designing steel structures for modular skids, catering to commercial and data center projects worldwide. Our comprehensive expertise, spanning steel member design, connection design, load calculations, fabrication drawings, and bill of material preparation, has earned us a reputation for delivering tailored solutions to clients in Europe, America, and Australia. This case study highlights our proficiency in designing steel structures for chemical injection skids, milk reception skids, and fuel gas booster skids, showcasing our ability to address complex challenges and deliver high-quality outcomes.

Project Scope

Our services encompass the full spectrum of modular skid design, with a focus on steel structures that ensure structural integrity and operational efficiency. We provide:

• Steel Member Design: Crafting robust structural components that meet industry standards.

• Connection Design: Engineering secure connections to withstand various loads and stresses.

• Load Calculation: Analysing static and dynamic loads, including seismic and wind forces, to ensure safety.

• Fabrication Drawings Creation: Producing detailed drawings for accurate manufacturing.

• Bill of Material Preparation: Customizing material lists to align with regional standards and client requirements.

Our experience includes designing steel structures for specialized skids, such as chemical injection skids for mining operations, milk reception skids for dairy processing, and fuel gas booster skids for industrial facilities. By adhering to local regulations and environmental conditions, we ensure compliance and performance across diverse markets.

Design Approach

We leverage advanced software tools to deliver precise and efficient steel structure designs. Our team is proficient in:

• Tekla Structural Designer: For structural modelling and analysis, simulating real-world conditions to optimize designs.

• Tedds: For detailed structural calculations, ensuring compliance with international codes.

• Ideastatica: For connection design, ensuring robust and safe connections.

• Advance Steel: For 3D modelling and detailing of steel structures, facilitating accurate fabrication.

• Revit: For building information modelling (BIM), enabling seamless coordination with other disciplines.

These tools, combined with our engineers’ expertise, allow us to create designs that are technically sound, cost-effective, and delivered on time. Our collaborative approach ensures that each skid is customized to meet the client’s specific needs.

Key Design Considerations

Designing steel structures for modular skids requires meticulous attention to several critical factors:

• Pipe Stress Analysis: We conduct comprehensive stress analyses to ensure piping systems can handle operational loads, thermal expansion, and vibrations, particularly for chemical injection skids where fluid dynamics are critical.

• Seismic Loads: In seismically active regions, we design structures to withstand specified seismic forces, complying with codes like EN, IBC 2015 and ASCE 7-10.

• Wind Loads: We calculate wind loads based on local conditions, designing structures to resist high winds, especially for outdoor installations.

These considerations ensure that our steel structures are durable, safe, and optimized for performance under diverse operating conditions.

Case Studies

The following recent projects illustrate our expertise in designing steel structures for modular skids:

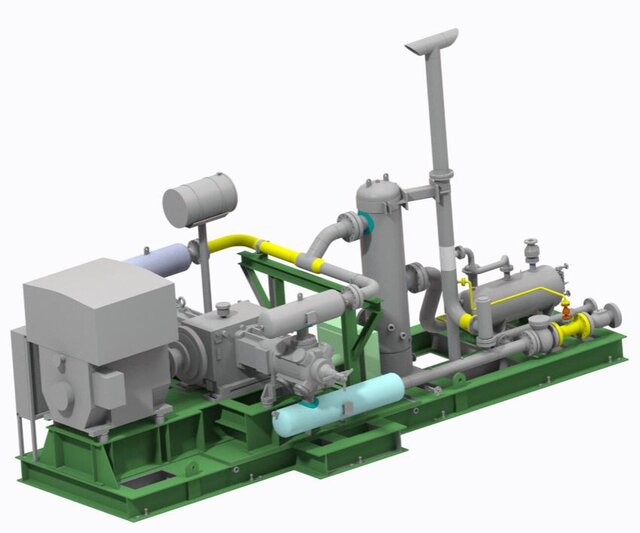

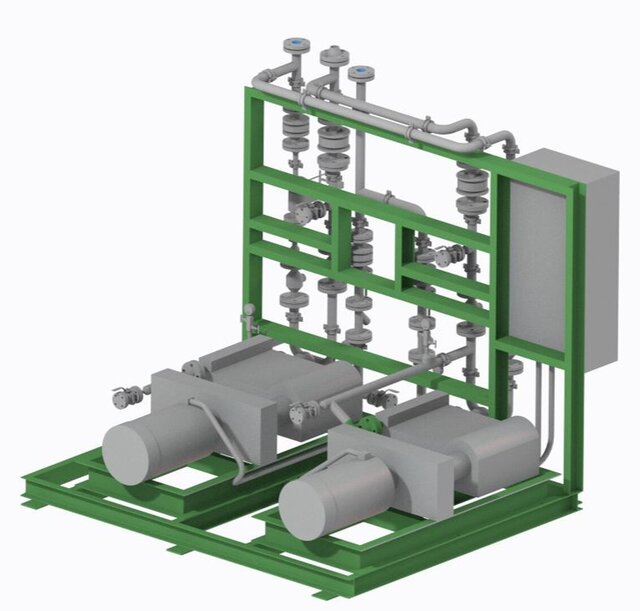

1. Data Center Power Distribution Skid

Project Overview: We designed a steel structure for a modular power distribution skid for a data center in California, requiring seismic qualification to withstand a magnitude 7.0 earthquake.

Challenges:

• Compliance with stringent seismic codes (IBC 2015, ASCE 7-10).

• Ensuring transportability and ease of on-site installation.

• Integrating heavy electrical equipment within a compact steel frame.

Solutions:

• Utilized Tekla Structural Designer to model and analyze the steel structure for seismic loads.

• Employed Revit for BIM coordination with electrical engineers, ensuring efficient equipment integration.

• Designed the steel frame with modular panels for easy access and maintenance, using Ideastatica for connection design.

Outcome: The skid was fabricated and installed successfully, providing reliable power distribution while meeting seismic safety requirements. This project underscored our ability to deliver critical infrastructure solutions.

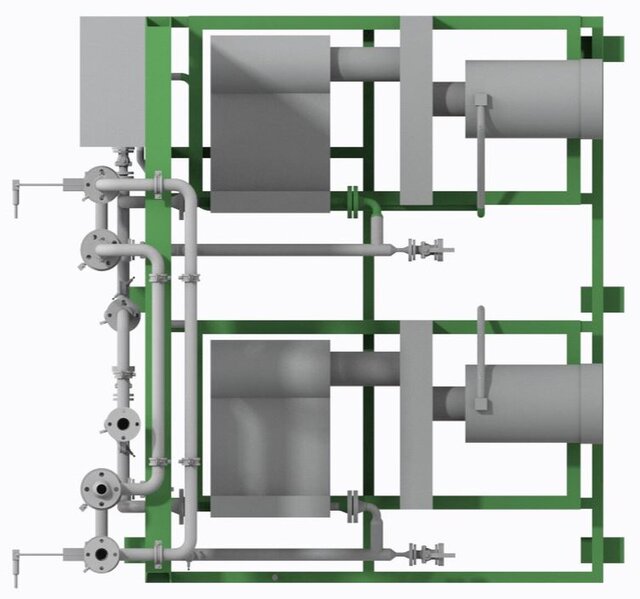

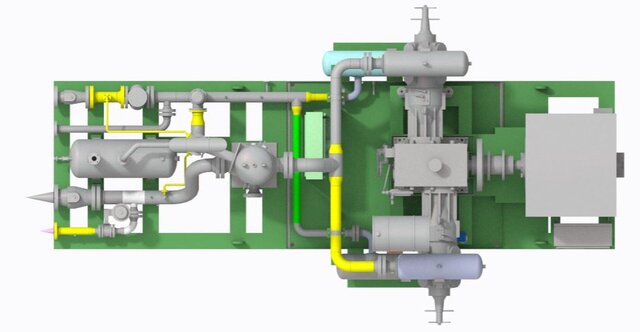

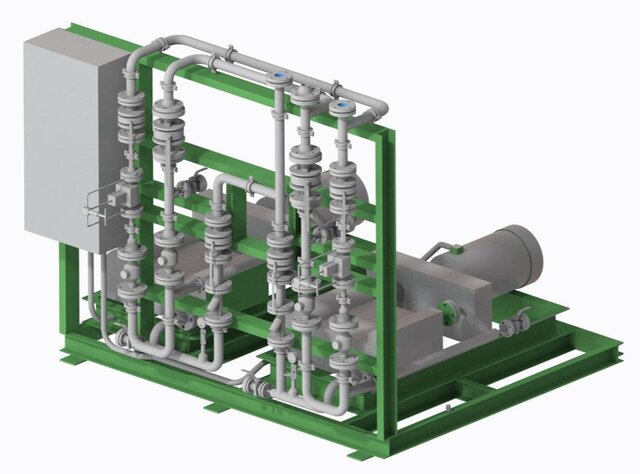

2. Chemical Injection Skid for Mining Operation

Project Overview: We designed a steel structure for a chemical injection skid for an Australian mining operation, operating in a corrosive desert environment.

Challenges:

• Ensuring corrosion resistance for long-term durability.

• Addressing extreme temperature fluctuations affecting material selection.

• Complying with Australian Standards for safety and environmental regulations.

Solutions:

• Selected high-grade stainless steel for the structural frame to resist corrosion.

• Used Tedds for thermal calculations to design insulation systems protecting against temperature extremes.

• Verified connection integrity with Ideastatica, ensuring compliance with Australian Standards.

Outcome: The skid performed reliably, supporting precise chemical injection and enhancing the mining operation’s efficiency while meeting environmental standards.

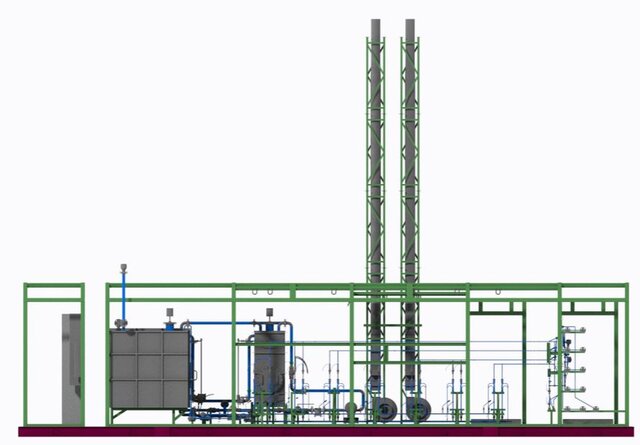

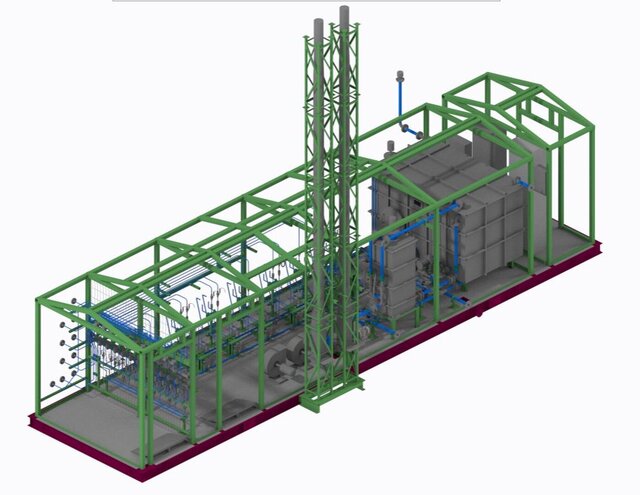

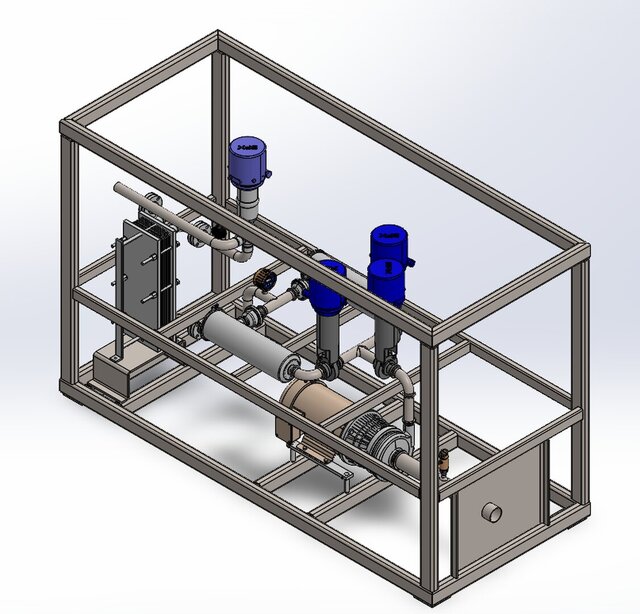

3. Milk Reception Skid for Dairy Processing Plant

Project Overview: We designed a steel structure for a milk reception skid for a European dairy processing plant, requiring strict hygiene and temperature control standards.

Challenges:

• Maintaining aseptic conditions to prevent contamination.

• Ensuring precise temperature control for milk processing.

• Complying with EU Regulation 852/2004 for food safety.

Solutions:

• Used food-grade stainless steel for the steel structure to ensure hygiene.

• Designed temperature control systems with Advance Steel for structural components, incorporating easy-clean features like sloped surfaces.

• Coordinated with process engineers using Revit to integrate monitoring systems.

Outcome: The skid facilitated hygienic and efficient milk reception, ensuring product quality and compliance with EU standards, enhancing the plant’s operational efficiency.

Benefits of Modular Skids

Modular skids with robust steel structures offer significant advantages:

• Faster Installation: Prefabricated modules reduce on-site construction time, minimizing disruptions.

• Cost Efficiency: Streamlined manufacturing lowers project costs.

• Flexibility: Scalable designs adapt to changing needs, ideal for evolving industries.

• Quality Control: Controlled fabrication environments ensure consistent quality.

These benefits make modular skids a preferred choice for modern commercial and data center projects, aligning with industry demands for efficiency and reliability.

Conclusion

We are highly experienced in designing steel structures for modular skids, delivering innovative and reliable solutions for global clients. Our expertise in steel member design, connection design, load calculations, and fabrication, combined with advanced software tools like Tekla Structural Designer, Tedds, Ideastatica, Advance Steel, and Revit, ensures that we meet the highest standards of quality and performance. Our ability to address challenges like seismic compliance, corrosion resistance, and hygiene standards demonstrates our versatility and commitment to excellence. As industries evolve, we remain dedicated to providing tailored solutions that drive success for our clients worldwide.