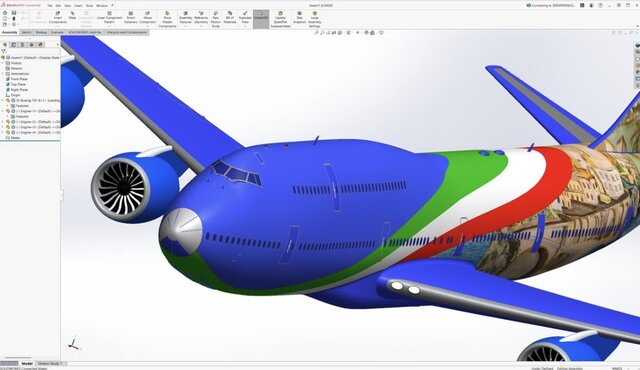

Boeing 747 aircraft 3D modeling and structural design using SolidWorks.

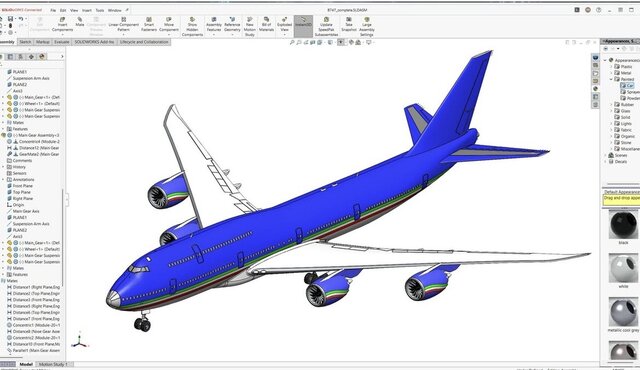

In this project, a complete 3D model of the Boeing 747 aircraft was designed using SolidWorks software.

The objective was to accurately simulate the structure of the fuselage, wings, engines, landing gear, tail, and internal components while considering aerodynamic and mechanical engineering principles.

Project Stages:

1. Dimensional Analysis & Reference Collection: Gathering blueprints, real aircraft dimensions, and technical specifications of the Boeing 747.

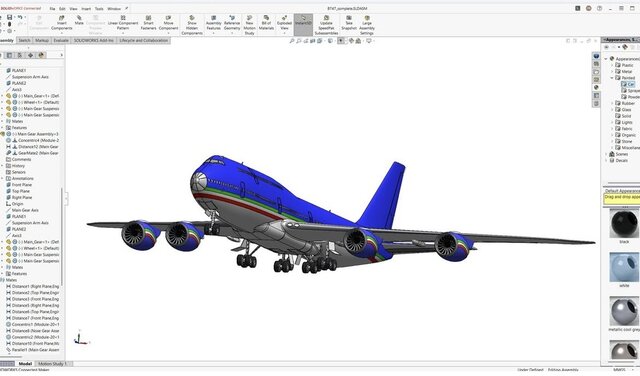

2. 3D Modeling of the Fuselage: Designing the outer shell and internal framework based on the actual curvature and proportions.

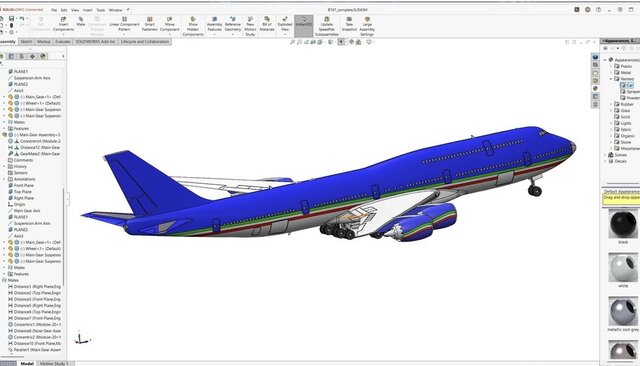

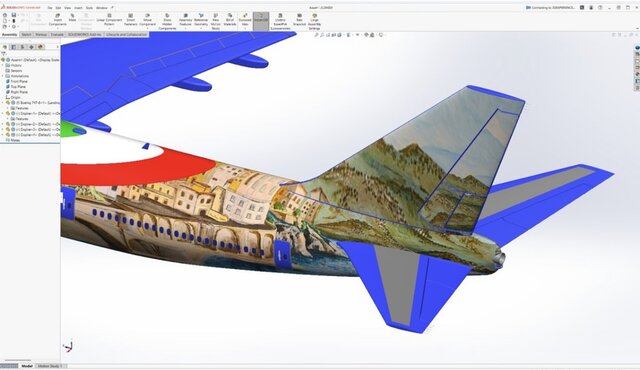

3. Wing and Control Surface Design: Detailed modeling of wings, flaps, ailerons, and flight control surfaces.

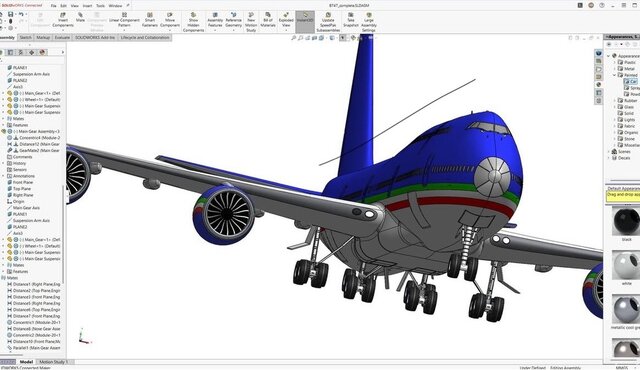

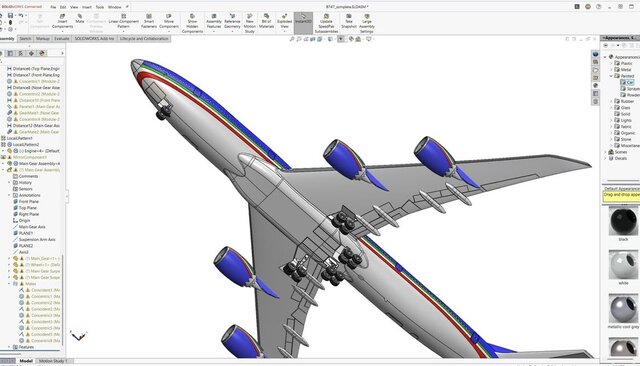

4. Landing Gear System Design: Including retractable mechanism details and wheel bay integration.

5. Turbofan Engine Modeling: Creating the turbine, air intake, exhaust nozzle, and wing mounting structure.

6. Full Assembly: Combining all parts into a single assembly file, checking for interferences and structural integrity.

7. Rendering and Final Presentation: Producing realistic renders with metallic materials, lighting reflections, and a sky background for professional presentation.

The final result is a highly detailed and analyzable 3D model of the Boeing 747, suitable for engineering studies, aerodynamic simulations, educational purposes, and industrial visualization.

Published