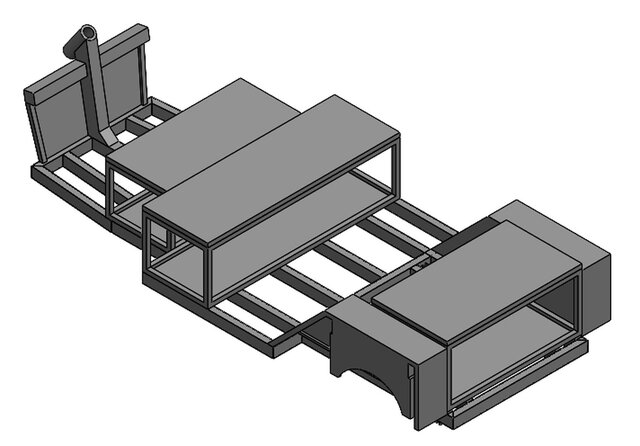

3-Wheeler E-Rickshaw Chassis | Modeling & Simulation

Reverse-engineered and designed the chassis of a commercial E-Rickshaw in SolidWorks, then performed static finite element analysis (FEA) in ANSYS. Compared rectangular, circular tube, and C-channel cross-sections using mild steel and aluminum alloys. Delivered manufacturing drawings, mesh models, and simulation results as part of a comprehensive engineering outcome.

Key Findings:

C-channel cross-section chassis exhibited the least deformation, lowest stress, and minimum weight across all tested materials.

All chassis variants were confirmed safe under specified loading conditions; simulated stresses remained below material yield limits.

Steel materials (AISI 1018, ASTM A302, Grade 201 SS) performed better overall than aluminum alloys, with only marginal differences between steel grades.

Aluminum alloys provided significant weight reduction, but with higher deformation compared to steel.

Recommended C-channel mild steel chassis as the optimal choice for strength, manufacturability, and reliability.

Featured visuals:

SolidWorks isometric CAD model

Technical fabrication drawings

Cross-section comparison diagrams

FEA mesh setup

Deformation and stress contour plots

Comparative results graphs for deformation, stress, and weight

Published