Design of a 50-Ton Hoist System for a Gantry Crane

Design of a 50-Ton Hoist System for a Gantry Crane

Project Overview

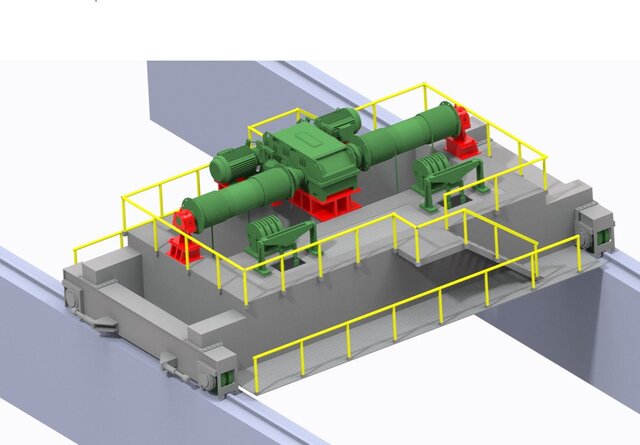

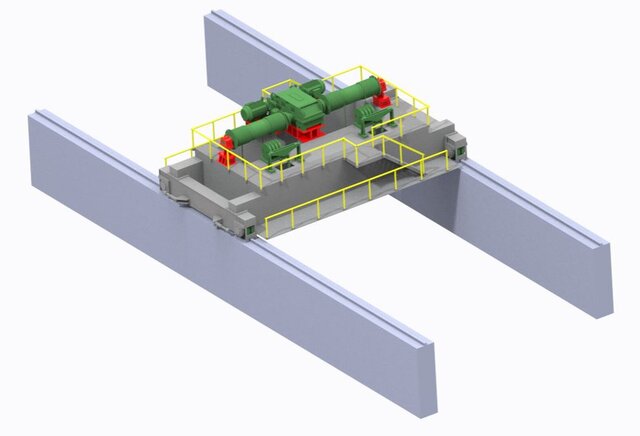

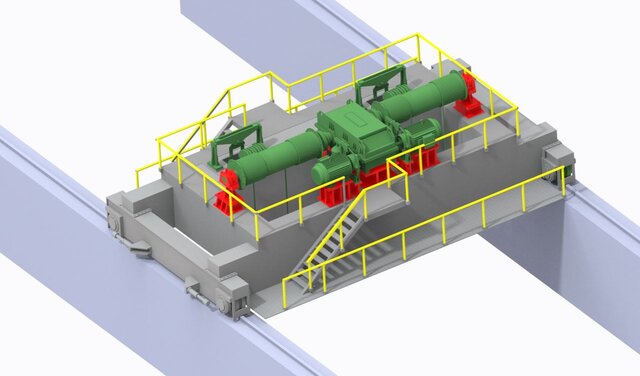

At Yas Tech. Services, we engineered a hoist system for a gantry crane with a safe working load (SWL) of 50 tons, designed for heavy-duty industrial material handling. The system lifts at 10 meters per minute, adhering to the FEM 1.001 standard for hoisting appliances. The project spanned concept design, component selection (motor, gearbox, brake, coupling, hoist drum, and steel supports), calculations, finite element analysis (FEA), and manufacturing drawings, ensuring safety, reliability, and performance.

Concept Design

The hoist system was designed to integrate with a gantry crane, providing precise and safe lifting. Key components included:

• Motor: A three-phase induction motor for reliable power.

• Gearbox: A helical gearbox for speed reduction.

• Brake: An electromagnetic brake for secure load holding.

• Coupling: A flexible coupling to connect motor and gearbox.

• Hoist Drum: A steel drum for wire rope management.

• Steel Supports: Robust structures to withstand crane loads.

Modelled in Unigraphics, the design prioritized compliance with FEM 1.001, focusing on structural integrity and safety.

Calculations

Calculations validated component performance:

• Lifting Power: For a 50,000 kg load with 4 rope falls (effective load: 12,500 kg) at 10 m/min (0.1667 m/s) was used to calculate power.

• Drum Speed: For a 0.5 m diameter drum, with a 1500 rpm motor, a 4:1 gearbox was chosen.

• Brake Torque: Drum torque: A brake with 11,496 Nm capacity (1.5 safety factor) was selected, meeting OSHA 1910.179 requirements.

Finite Element Analysis (FEA)

FEA, conducted using ANSYS, ensured component durability:

• Hoist Drum: Maximum stress was 250 MPa, below the 350 MPa yield strength of high-strength steel, with a safety factor of 1.4.

• Steel Supports: Analysed for dead, live, and wind loads, with maximum stress at 200 MPa and deflection <5 mm, complying with FEM 1.001.

• Fatigue analysis confirmed over 500,000 cycles, ensuring long-term reliability.

Manufacturing Drawings

Detailed drawings were produced in Unigraphics, specifying:

• Components: Dimensions, tolerances (±0.1 mm for mounting), and high-strength steel with corrosion-resistant coatings.

• Assembly: Integration details for motor, gearbox, and supports.

• GD&T: Flatness (±0.05 mm) and positional tolerances per ASME Y14.5.

Key Technical Challenges

• High Load Capacity: Designing for 50 tons required robust components while minimizing weight.

• Safety Compliance: Meeting FEM 1.001 and OSHA standards demanded rigorous analysis.

• Fatigue Resistance: Ensuring durability under repetitive loading was addressed through material selection and FEA.

• Component Integration: Seamless operation of motor, gearbox, and brake was achieved through precise design.

Our Contribution

Our team’s expertise drove the project’s success:

• Component Selection: Chose optimal components

• Standards Adherence: Ensured compliance with FEM 1.001, ASME Y14.5, and OSHA 1910.179.

• Collaboration: Partnered with manufacturers for cost-effective production.

Additional Considerations

• Safety Features: Included emergency stops, overload protection, and secondary brakes.

• Maintenance: Designed for easy component access, using durable materials.

• Sustainability: Optimized motor efficiency to reduce energy use.

Conclusion

This project showcases our ability to deliver a high-capacity hoist system for a gantry crane, meeting stringent standards. Through advanced engineering and collaboration, we provided a safe, reliable solution for industrial lifting.